Guide to dark radiators – Heating halls in an energy-efficient and cost-effective way

What is a blackbody radiator (really)?

In everyday life, the term "dark radiator" is often equated with infrared radiant heaters. It is also frequently used to refer to electric infrared heaters. Some even refer to them as electric dark radiators. From a technical point of view, however, this is not entirely correct.

Dark radiators in the true sense of the word are gas-powered infrared heating systems that bring heat into halls in a particularly efficient manner. To do this, gas is burned in a closed pipe. The heat is transferred via this pipe to reflectors, which direct it into the room. And because the combustion takes place in a closed system and is not visible, these are referred to as dark radiators. The result: even, draft-free, and highly efficient heat—even in the largest industrial or logistics halls.

The heating principle is easy to explain: dark radiators do not heat the air, but emit infrared radiation. When these rays hit solid surfaces—such as the floor, machines, or people—they generate pleasant warmth. The air in the room remains unaffected. This almost completely prevents heat loss under the hall roof.

KÜBLER offers a wide range of infrared heating systems—from classic gas-powered dark radiators to the new energy-flexible solutions. The Fair.AIdH technology enables you to flexibly exploit the advantages of the dark radiator principle with various energy sources such as gas, biogas, hydrogen, or electricity. This means that your hall heating system not only remains efficient, but also future-proof and independent of cost developments or the availability of individual energy sources.

The pillars of efficiency in modern dark radiators in halls

The energy efficiency of dark radiators is determined by several technical factors. The decisive factors are direct radiant heat without losses due to rising warm air, zone-based heating as required, precise control of energy consumption, rapid heating and cooling, and the possibility of utilizing residual heat and integrating various energy sources.

Radiant heat instead of warm air

Dark radiators work on the principle of infrared radiation. They do not heat the air in the room, but transfer energy in the form of electromagnetic waves. When these waves hit solid objects such as floors, machines, or people, the radiation is converted into heat. This creates an even, draft-free indoor climate that resembles the natural warmth of the sun.

Unlike warm air systems, it is not necessary to first heat the entire room volume with warm air, which first collects under the hall roof until it slowly accumulates downwards (where it is actually needed). The heat is generated directly in the area of use. This reduces energy losses and ensures that even when doors are open or usage changes, heating is only provided where it is actually needed. This physical principle is the basis for the high efficiency and high savings potential of modern dark radiators.

Zone heating as needed

Dark radiators allow heat to be directed precisely where it is needed. Instead of heating an entire hall evenly, individual areas or work zones can be controlled separately. This means that occupied zones are heated to a comfortable temperature, while the heaters in areas that are not currently in use can simply be switched off and do not consume any energy.

This demand-based heating system offers a significant efficiency advantage, particularly in halls with varying usage or partial occupancy. Whether for production, storage, or shipping, each zone can be controlled independently and activated only when needed. This significantly reduces energy consumption and operating costs without compromising thermal comfort for employees.

Intelligent controllability and control technology

A key efficiency factor of modern dark radiators is their precise control. Digital control systems allow energy consumption to be adjusted precisely to temperature, usage, and hall zones. This means that the systems only heat when and where heat is actually needed.

With CELESTRA KÜBLER has developed a modular control system that combines these functions. It enables the entire heating system to be controlled precisely in terms of time and zone, thereby contributing significantly to the optimization of energy consumption. In conjunction with the Energy Monitoring & Management Application EMMA Operating data is collected, analyzed, and documented—an important basis for certifications such as DIN EN ISO 50001.

Depending on the project, intelligent control can achieve additional energy savings of up to 20 %. This makes control technology a key component for efficiency, transparency, and cost-effectiveness in hall operation.

Immediate heating and cooling

Dark radiators react quickly. Since infrared radiators do not heat air masses but emit radiation energy directly, the heat is available immediately after switching on. When the heating is switched off, the heating effect ends just as quickly.

This response speed makes it possible to tailor heating operation precisely to actual usage times. In shift operations or halls with changing occupancy, heating can be flexible and efficient—without long lead times or unnecessary energy consumption. Fast heating up and down thus contributes significantly to overall cost-effectiveness and energy savings in operation.

Use of waste heat and energy flexibility

In addition to direct radiant heat, modern systems also utilize the energy generated during the heating process itself. With the H.Y.B.R.I.D. system (KÜBLER) gas-powered infrared heaters such as PRIMA, OPTIMA plus or MAXIMA combined with condensing technology and digital controls. The residual heat contained in the exhaust gas is recovered using O.P.U.S. X condensing technology and fed into hydraulic office heating systems, for example. This allows up to 15 % of additional energy to be recovered.

Energy flexibility is a new and very important efficiency factor. The latest generation of heating systems from KÜBLER expands on the advantages of the dark radiator principle with some crucial new technical possibilities. This technology is called Fair.AIdH and can be operated with different energy sources—from natural gas and biogas to hydrogen or electricity. Systems such as FUTURA or MAXIMA E-Hybrid automatically adapt to the available energy source, enabling economical, future-proof hall heating. Fair.AIdH „dark radiators“ thus contribute not only to energy efficiency, but also to decarbonization in line with the energy transition.

Energy efficiency as the key to the energy transition

Energy efficiency is the decisive factor in achieving climate targets economically. Dark radiators come into play here by reducing energy consumption to a minimum and minimizing losses. The radiation principle ensures that heat is generated directly in the area of use instead of remaining unused under the hall roof.

In practice, modern infrared heating systems from KÜBLER can achieve energy savings of up to 70% compared to conventional warm air systems, depending on the geometry and use of the hall. Complemented by digital controls, waste heat utilization, and flexible energy sources, energy consumption is further optimized. Dark radiators combine high efficiency with measurable CO₂ reduction, making them a cornerstone of the energy transition in hall areas.

In accordance with the “Heating Act”: GEG-compliant and future-proof heating

The Heating Act (Building Energy Act, GEG) stipulates that heating systems in new buildings must be powered by at least 65% renewable energy in the future. This poses particular challenges for newly constructed industrial and commercial buildings, as the physical conditions differ significantly from those of traditional buildings. Efficient infrared radiant heaters offer solutions that can be implemented both economically and in compliance with the law – in new and existing buildings alike.

New buildings: Plan efficiently and meet the 65 percent requirement

The 65 percent requirement applies directly to new buildings. This means that the majority of the energy used must come from renewable sources. The new Fair.AIdH systems can meet this requirement when integrated into an energy-flexible concept.

Modern infrared heaters such as FUTURA or MAXIMA E-Hybrid are designed to use various energy sources – such as biogas, hydrogen, or electricity from photovoltaics or wind power. Depending on the location and energy infrastructure, the renewable share can be increased to 100% immediately or gradually.

Intelligent control plays a central role here: digital control systems such as CELESTRA record consumption data, adjust operation to actual heat demand, and enable the targeted use of renewable energies as soon as they become available. This allows legal requirements to be met without compromising operational safety or economic efficiency.

Existing buildings: GEG compliance through proven efficiency

For existing buildings, the principle of „efficiency before energy source change“ applies. Heating systems that achieve at least 40% energy savings compared to the old system are exempt from the obligation to use renewable energies according to the law. This regulation is particularly important in the case of renovations where complete replacement or conversion to renewable energies would not be economically or technically feasible.

Dark radiators often clearly meet this requirement in practice. Depending on usage and hall geometry, the infrared principle, zone-based heating, and precise control can save 50, 60, or 70% energy. Systems such as H.Y.B.R.I.D. with O.P.U.S. X Exhaust gas heat recovery systems further increase efficiency. The Energy Monitoring & Management Application (EMMA) supports operators with documentation and verification by transparently recording, analyzing, and documenting energy flows—an important basis for GEG-compliant planning and certification in accordance with DIN EN ISO 50001.

Comparison: Dark radiators vs. heat pumps in industrial buildings

Heat pumps are considered a key technology in the energy transition. But does this apply to all buildings? In industrial halls, they usually reach their physical and economic limits. The reason is quite simple: heat pumps are not heaters, but purely heat generators, just like oil, gas, or wood chip boilers. To transfer the heat into the hall, they require additional technology, such as underfloor heating or a warm air blower. Neither of these are very functional in halls. In addition, the heat pump loses efficiency due to storage tanks and pipes for heat transport. Dark radiators work on a different principle—they are heat generators and heat transfer devices in one system and generate heat exactly where it is needed. The following comparison provides an overview of the most important differences:

| criterion | Dark radiator (infrared) | Heat pump |

| Technology | 2-in-1 heat generator and transfer unit | Heat generator. Additional technology required for transfer, e.g., underfloor heating, fan heating |

| Installation | Under the hall ceiling | Underfloor heating: heating coils in the hall floor (restricts use)

Fan heater: under the hall ceiling or on the side walls |

| heat principle | Infrared radiation heats surfaces, people, and objects it hits (sun principle). Warmest spot: lower hall area | Air- or water-based convection, heats room air |

| field of application | Halls with dynamic temperature requirements, ceiling height > 4 m, and large room volume | Rooms with constant temperature requirements and floor heights of 2.50 to 3.00 m (apartments, offices, etc.) |

| response time | Fast (short heating time) | Sluggish, depending on the air volume |

| operating time | As needed | Mostly 24/7 |

| zone heating | Possible | Not possible |

| Energy losses in high-ceilinged halls | Low – no heat under the roof, no air exchange | High – rising warm air, additional energy losses via storage tanks and pipes |

| energy source | Gas, biogas, hydrogen, electricity (energy-flexible) | Electricity, usually sourced from outside air or the ground |

| GEG compliance | Existing buildings: realized energy savings ≥ 40 %, no obligation to use renewable energies

New construction: 65 % requirement can be met through energy flexibility and high efficiency |

65 % requirement can be met by using electricity |

| Investment & Amortization | Moderate investment, payback period usually 2–5 years | Higher initial investment, longer payback period |

| Cost-effectiveness for large room volumes | Very high (zone heating and demand-based operation) | Significantly reduced due to large air masses and heat losses |

Classification:

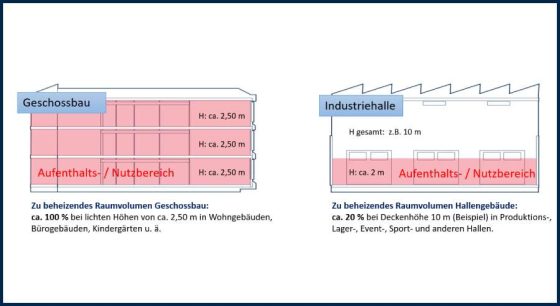

Both systems can contribute to decarbonization, but differ in their system logic. While heat pumps show their strengths in lower rooms (multi-story buildings) with uniform heating requirements, dark radiators impress in large halls (single-story buildings) with their efficiency, flexibility, and short response times. In combination with digital control and multi-energy technologies, they meet the requirements of the Building Energy Act as well as the practical requirements for economical hall operation.

Conclusion: Why dark radiators make your hall fit for the energy transition

Dark radiators combine technical efficiency with future-proofing. The infrared principle generates heat directly in the area of use—without unnecessary losses under the hall roof. In conjunction with modern control technology and zone-by-zone regulation, energy is only used where it is actually needed. This significantly reduces consumption and measurably lowers CO₂ emissions.

In practice, modern infrared heating systems can achieve energy savings of up to 70% compared to warm air systems. This means that dark radiators meet a key requirement of the energy transition: maximum efficiency combined with high cost-effectiveness.

Whether in new buildings or renovations, the combination of efficient radiant heat, intelligent control, heat recovery, and flexible energy use makes dark radiators one of the most reliable solutions for designing hall heating systems that are GEG-compliant, economical, and climate-friendly in the long term.

-

"Heating with the windows open" in private households is like "heating with the doors open" in production halls and warehouses. It's great if you can afford this in industry and commerce because production and business are obviously running - unfortunately, this is not a matter of course for many companies in times of coronavirus.

-

Heating industrial and event halls economically and flexibly: radiant heaters are ideally suited for this job. An overview of how they work, types and possible applications.

-

The metalworking company "Die Kanter & und Schlosser" heats its new building variably with electricity, hydrogen or gas thanks to the world innovation from KÜBLER in Ludwigshafen.

-

How is energy used correctly? What does efficiency mean? In the German government's current energy policy, there is a huge gap between aspiration and reality. After all, industrial buildings are not treated as industrial buildings because they only account for two percent of buildings - even though they are responsible for 15 percent of greenhouse gas emissions. The latter has not played a role to date. Behind this two percent are 420,000 to 480,000 hall buildings that are used in industry, commerce and municipalities as production halls, logistics halls, workshops, sports halls or sales outlets. A small number that is responsible for a significant proportion of energy consumption and GHG emissions in Germany.