Traditional gymnastics club 1860 Mußbach e.V. enjoys the new feeling of warmth thanks to KÜBLER hall heating systems

The old fan heating had long been a source of dissatisfaction among club members. Problems such as dust and air turbulence as well as a lack of volume control were acute challenges in the gyms. The varied training times required a precise and flexible heating solution that the previous system could not provide.

Under the leadership of Dieter Hackebeil, the former chairman of the association, the project to renew the hall heating system was tackled. After conducting his own research, Hackebeil came across KÜBLER GmbH. Impressed by the competence and unobtrusiveness of the consultant Mr. Bolch, the decision in favour of KÜBLER was quickly made.

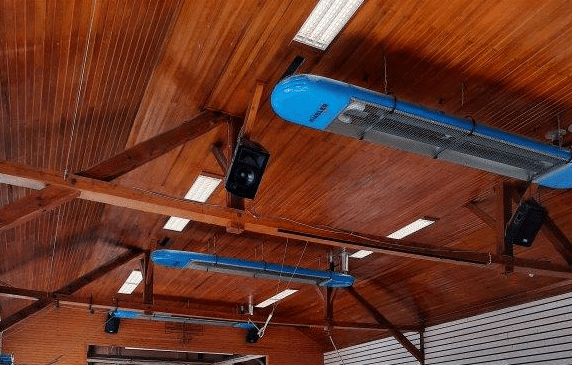

The new hall heating system was commissioned on 08.08.2017 and gave the club members a new feeling of warmth during the first heating period in the same year. The radiant heat concept from KÜBLER proved to be extremely pleasant and efficient, as it brings the heat directly to where it is needed.

Thanks to various trial runs, energy savings of 40-50 % were already achieved in the first year. The satisfaction of the athletes has increased significantly, while the costs for the club have fallen considerably.

"The hall heaters from KÜBLER have never disappointed us in recent years and have always been a source of great enthusiasm," emphasizes an enthusiastic club member.

"I am also always happy to recommend KÜBLER hall heating systems. Not because I benefit from it, but because I am very deeply convinced of the technologies and I am happy to use my voice to encourage even more hall operators or owners to switch."

Dieter Hackebeil adds.

KÜBLER GmbH is delighted that its indoor heating systems have helped Turnverein 1860 Mußbach e.V. to create a new feel-good atmosphere. "We are proud that our technology is helping to meet the needs of sports clubs and their members in the best possible way."

Explains Thomas Kübler, Managing Partner of KÜBLER GmbH.

"KÜBLER will be back here in Mußbach at some point, you have to keep up with the times."

Says Dieter Hackebeil, indicating that the partnership between the club and KÜBLER will remain promising in the future.

We look forward to your publication!

Interested in our press photos?

Would you like to download all images from the article in the highest quality? Simply click on the button below and enjoy our press photos in the highest resolution!

-

While the public debate has so far focused heavily on residential construction, specific questions arise for industrial and logistics companies: what are the implications for large-volume non-residential buildings such as production and logistics halls? Thomas Kübler, an expert in energy-efficient hall heating systems, explains the key points from a practical perspective. Climate neutrality remains the guiding principle The German government is sticking to its goal of climate neutrality [...]

-

„Anyone who is nominated for the ‘Großer Preis des Mittelstandes’ belongs to the elite of German SMEs. This nomination alone is already an award of the highest quality,“ emphasizes Barbara Stamm, President of the Bavarian State Parliament. Outstanding achievements in five areas In the competition, the KÜBLER company is assessed in its entirety and its role within society. The [...]

-

Ludwigshafen - Clear messages, clear expectations: At the annual reception of the Rhineland-Palatinate Economic Council at the main site of KÜBLER GmbH, host Frederic Renz had clear words to say about the economic situation. „SMEs need what all companies in Germany urgently need: a clear direction and reliable political framework conditions. If you want economic growth, you have to create planning security,“ emphasized the Managing Director of the hall heating specialist. Around [...]

-

Heating halls efficiently, economically and functionally is a challenge. Because in these huge buildings with ceiling heights that often reach 20 meters, a lot of energy can quickly be consumed - energy that is expensive and, depending on the heating technology used, also causes high emissions. The building stock is often still equipped with inefficient and [...]