Amendment to the Building Energy Act: FDP announces switch from energy efficiency to emission efficiency

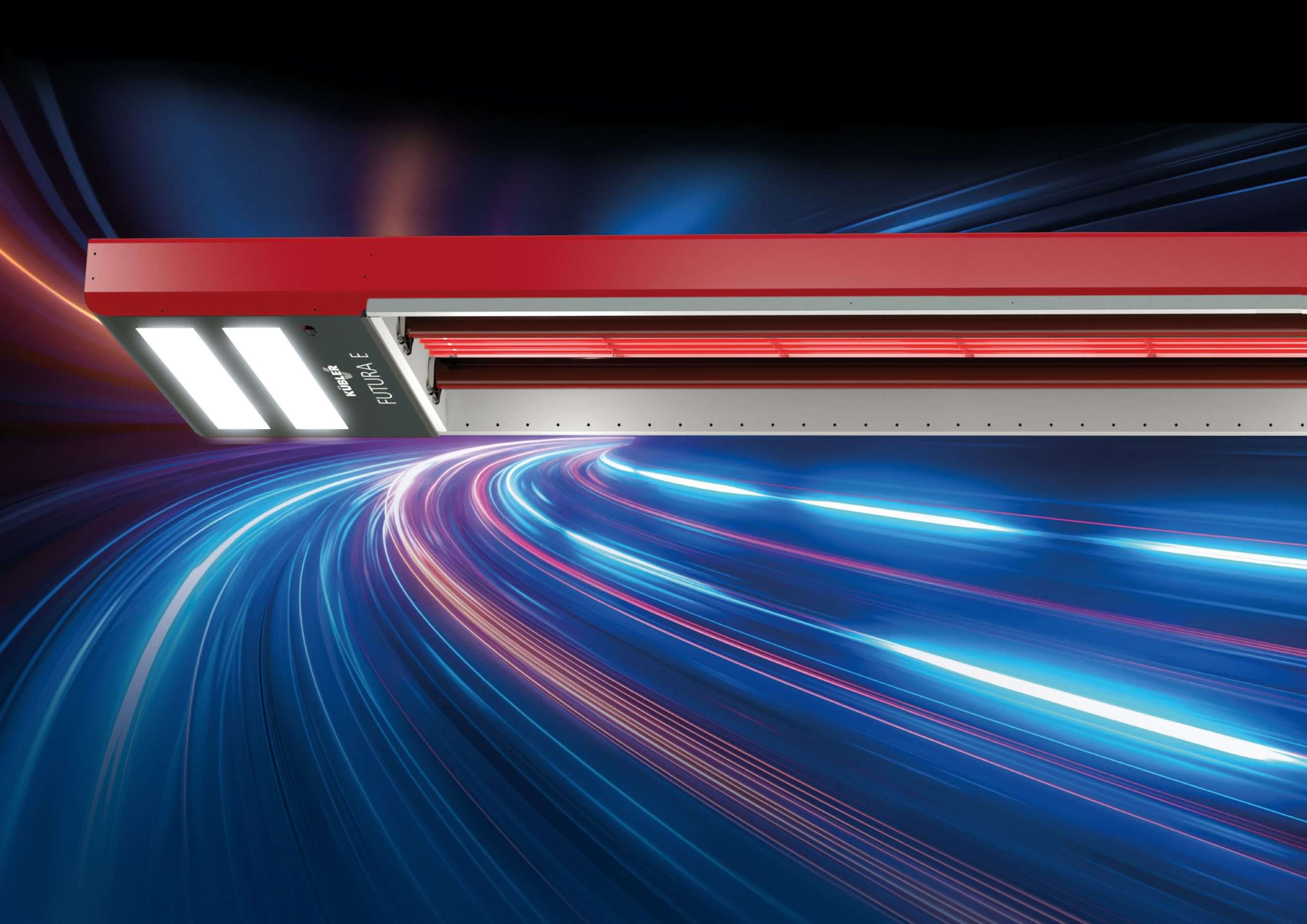

The industry is in a debate between regulation and feasibility as well as between focus and openness to technology. Thomas Kübler founded the company of the same name 30 years ago and set up his own R&D unit. Five years ago, the company began developing FUTURA, an innovation for the energy transition. To mark the launch of this unique infrared heating system for industrial halls, experts discussed the challenges of the energy transition. An excerpt from the expert dialog:

Daniel Föst MdB, Building and housing policy spokesman for the FDP parliamentary group in the Bundestag:

"We will have a major amendment to the Building Energy Act next year. At the moment, I have the impression that we are getting bogged down.

I think we need to do more to resolve the system problem. That's why I think it makes sense to change the GEG from energy efficiency to emissions efficiency. We should define how CO2 and not concentrate on a single technology.

Our benchmark should be emissions efficiency."

Franz Untersteller (The Greens), Former Minister of the Environment of the State of Baden-Württemberg:

"It's not enough to say that we want 65 percent renewable energy when installing new heating systems from 2024.

It is important that we use CO2 avoid. No matter what technology. Some of the debates in Germany make me think: crazy.

We need more pragmatism, that doesn't hurt in Berlin either. I would like to see more pragmatism, because we are talking about CO2savings - and cost-effectively.

Why should Norway only build green hydrogen, but not blue hydrogen as well? I can't see where the problem lies. If Norway goes through with it and we in Germany continue to focus on green, it may be that an energy-intensive company will move away from Germany.

We have been discussing the introduction of smart meters for eight years. I have the impression that there are two or three people in the authorities who want to make everything more and more complicated.

We urgently need to differentiate in the GEG. A daycare center is different from a 40-meter-high hall."

Michael Hauer (The Greens), State Secretary in the Ministry for Climate Protection, Environment, Energy and Mobility of the State of Rhineland-Palatinate:

"KÜBLER GmbH is a beacon in Rhineland-Palatinate. I hope that the innovations that come from here will also be implemented by the entire state. The development of FUTURA is a great opportunity to access energy when it is needed.

We will have to change our behavior and business models. Climate protection targets can no longer be postponed. We need a regional energy transition. And we need technological openness.

We are working with Berlin on a daily basis and will drive forward the GEG in such a way that differentiation takes place in non-residential buildings."

Prof. Dr. rer. nat. Svenja Carrigan, TU Kaiserslautern, Professor of Building Physics Modeling:

"Europe is turning away from primary energies - towards saving CO2Which energy system can I use and how? We don't just need to focus on the operation of an energy source, but on the entire life cycle. We need to become more decentralized and think bigger."

Thomas Niederhofer, Managing Director of the Knauf Interfer Business Unit Steel

"We need new incentives. As a company, we have so much space that we can also install photovoltaics on the ground. But we also need to have the option of crediting electricity and not just blindly firing it into a system. We need more flexibility. In Holland, e-cars are charged at night and used as a battery station during the day when they are not needed as a car.

We have large halls in almost every federal state. First of all, we try to avoid using energy in order to reduce CO2 to reduce energy consumption. In a very large hall that has just been converted, we will save around 76 % of energy from now on because we have opted for KÜBLER technology. With this investment, we have a roi (return on investment) of just 2.5 years! You don't have to carry the child to the well, but it's an entrepreneurial motivation to simply do it. The technology is there.

We have also calculated heat pumps for ourselves. We would need a 1000 kilowatt power supply line for this hall. Our energy supply company won't go along with that. It won't work with a heat pump. We also can't install underfloor heating because our floors have to be designed for heavy loads, which no underfloor heating can survive. And radiant ceiling panels on the roof weigh 4 to 5 times more than the KÜBLER technology. The statics of the hall can't withstand that. And even if it did, there would be no static capacity for PV at all. Heat pumps in halls don't work."

Dr. Robert Seguin, Energy and grid specialist, Manager THEMA Consulting Group AS in Oslo/Norway:

"In Norway, 100 percent of energy is renewable thanks to hydropower. The energy system's dependence on the weather will increase the need for flexibility. Without flexibility in the system, the conversion of the energy system will be expensive. Flexibility is needed to cover demand, for the grid and for system stability."

Thomas Kübler, Managing Partner of KÜBLER GmbH:

"We are all the energy transition. Everyone can make their contribution. We do not have to and should not wait for anyone. We can only expect political decision-makers to draw on the expertise of business and science and incorporate it into their decision-making processes.

Companies that reduce their green footprint must be supported. Every euro invested there comes back several times over in taxes. Dear politicians, don't be so stingy.

There is no ideology-bound solution. Make the Building Energy Act open to all technologies!

We are going the wrong way. We must not fight the pain, we have to tackle the causes. Energy that is not needed is good energy.

Flexible tariffs and volatility are essential if the energy transition is to succeed.

We can do the energy transition, we are ready for the energy transition - if we are allowed to. With more flexibility and an openness to technology."

The expert dialog with presenter and ARD climate expert Thomas Ranft can be viewed in full at https://www.youtube.com/watch?v=ej6OX0eMYWM

You can also listen to the Deutschlandfunk report: https://www.deutschlandfunk.de/wahre-energieschleudern-wie-in-industriehallen-energie-gespart-werden-kann-dlf-d0ebf38e-100.html

To the FUTURA:

KÜBLER GmbH is a classic niche expert for heating systems in industrial halls. The Ludwigshafen-based company has its own R&D unit. The latest development from this product forge is the FUTURA, which works independently of the energy source. The infrared heating system for halls uses hydrogen, electricity, gas or a mix of these. It can process green and fossil fuels highly efficiently, thus building a bridge to the carbon-free era.

This works both in mono mode and in mixed mode. Depending on which energy is currently available or particularly cost-effective. "In this way, we ensure security of supply and stabilize the grids," says Thomas Kübler. "But above all, our solution is economical. Infrared is the ideal way to heat large rooms." This refers in particular to halls with a height of four meters or more. The innovative solution also integrates the LED lighting of hall buildings in a single device and can be used for new buildings as well as for the energy-efficient refurbishment of existing buildings.

The state of Rhineland-Palatinate has already awarded the company the "Innovative Technology for Climate Protection" innovation prize for the FUTURA as part of the SUCCESS 2022 competition.

Background:

With ceiling heights of 4 to 40 meters and areas of up to 10,000 square meters and more, their room dimensions cannot be compared with apartments, offices or daycare centres, which are usually built as multi-storey buildings with clear heights of around 2.50 meters. This also applies to the heating of such room colossi - it is incomparably more demanding than in the much lower multi-storey buildings. However, this differentiation is not made in the planned 65% renewable energy rule in the Building Energy Act.

"If such large rooms are to be heated in an energy-efficient manner, very special technologies are required. Rarely has it been as urgent as it is today to use all the technological resources available to us to effectively counter the energy crisis," says Thomas Kübler. He is a proven expert in heating industrial halls.

Kübler says: "Efficient heating is about providing heat with as little loss as possible in the areas of the hall where people work and need heat. As a rule, this is not at a ceiling height of 10 or 20 meters, but in an area around 2.00 meters above the hall floor." This cannot be ensured with a heat pump either. The technology is not made for this.

The efficiency of special hall heating technologies can be seen in energy refurbishment projects for industrial halls. Savings of up to 70 percent are realistic. This relieves the financial burden on companies with cost savings of several tens or even hundreds of thousands of euros per year, depending on the size of the project. The greenhouse gas reductions are correspondingly high.

For this reason, a revision of the Building Energy Act is necessary, in which openness to technology and differentiation between different types of non-residential buildings should be fundamental.

-

If you are reading this article, you are probably looking for an efficient way to heat your industrial or commercial building. During your research, you have already come across one or other technology such as dark radiant heaters or hot air. Now you want to know why dark radiant heaters in particular are repeatedly highlighted as especially efficient. We'll tell you!

-

Are you looking for an economical and sustainable heating system for your new building? Then you should invest enough time in planning. And avoid the following mistakes.

-

According to the IMD Competiveness Ranking 2024[1], our once leading industrial nation has slipped from 6th to 24th place in just ten years. 45 percent of industrial companies with high electricity costs are planning or implementing plans to reduce their production or relocate it abroad. And the trend is rising[2]. Increasing bureaucratic costs and the extremely high level of energy prices in our country are causing many companies to [...]

-

The energy crisis is currently leaving no one indifferent. Everyone is desperately looking for ways to get consumption and costs under control to some extent. The German government's price brake will not take effect until March 2023, and even then, the prices for 30 percent above the basic quota for industry and 20 percent for small and medium-sized enterprises will still be subject to the wild market conditions next year. So what to do?