KÜBLER hall heating systems

Workshop hall heating systems

With infrared workshop heaters from KÜBLER, you can reduce your energy costs and create pleasant working conditions right at the workplace—even when the door is open.

KÜBLER hall heating systems

Why infrared heaters are particularly well suited for workshops

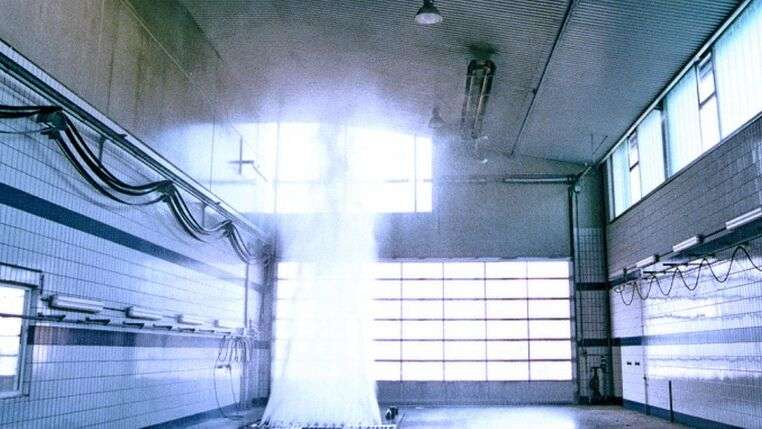

Open doors, changing usage, sporadically occupied workstations – economical heating is a real challenge in workshops. Conventional heating systems mainly heat the air – which escapes every time the air is exchanged. Infrared heat works differently: it acts directly at the workstation, where it is needed. This creates a pleasant working environment. At the same time, energy consumption is noticeably reduced. KÜBLER systems can be operated with gas or electricity and are therefore flexible in their planning – even for locations without a gas connection.

All advantages at a glance

Effective workshop heating: infrared technology from KÜBLER

KÜBLER infrared heating systems are designed for efficient use in halls – and thus meet the special requirements of workshops. The advantages at a glance:

Infrared heaters from KÜBLER save up to 70% energy compared to conventional systems. Because the heat is directed specifically at the work area, only the zones that are actually used are heated—this permanently reduces energy consumption and noticeably lowers your operating costs.

Unlike warm air or slow-acting water systems, infrared heaters deliver heat almost at the touch of a button. The effect is immediately noticeable—ideal for workshops with shift work or changing occupancy. This means you only heat when and where it is needed.

Whether it's a single workbench or an entire section of a hall, infrared technology allows you to target specific areas. This zone-specific heating ensures maximum flexibility and prevents energy from being wasted in unused areas.

The heaters are mounted under the ceiling and take up very little space. This is particularly advantageous in workshops with relatively low ceilings or limited space. All work and traffic areas remain freely usable.

Because no air is moved, there is no air flow. This means no dust is stirred up and there are no unpleasant draughts. This is a real plus for comfort and cleanliness, especially in workshops with dust exposure or sensitive machinery.

Infrared heating systems from KÜBLER operate reliably—even in harsh workshop environments. Their robust construction ensures a long service life, low susceptibility to faults, and low-maintenance operation—an advantage for businesses that depend on reliability.

Compared to complex central heating systems, the initial costs for infrared solutions are manageable. Simple installation and modular expandability further reduce the initial investment—with a quick return on investment thanks to low operating costs.

Optional integrated heat recovery allows waste heat from the heating process to be used for hot water production. This further increases the system's energy efficiency—and significantly reduces your energy costs.

The advantages of infrared

What energy source do you want to use to heat your workshop?

Not every workshop has the same conditions—and not every heating system is suitable for every energy source. Whether gas, electricity, hydrogen, or a combination of several: with KÜBLER's energy-flexible solutions, you will find the right system for your infrastructure and your heating requirements.

Hybrid multi-energy hall heating systems

Flexible energy thinking: KÜBLER's multi-energy systems combine various sources such as gas, electricity, or hydrogen—depending on availability. For maximum supply security.

More about hybrid infrared hall heaters from KÜBLER

Electric infrared hall heaters

Heating with electricity – clean, direct, and ideal for workshops with PV systems or without gas connections. KÜBLER's electric infrared solutions deliver precise heat – 100% CO₂-free.

More about KÜBLER's electric infrared hall heaters

Gas infrared hall heaters

For over 35 years, KÜBLER has been developing powerful, gas-powered infrared systems for industrial buildings. In workshops, they impress with their high efficiency, short payback periods, and clear savings potential—even on a limited budget.

More about KÜBLER gas infrared hall heaters

Hydrogen hall heaters

The green gas of the future – scalable for use in hall heating systems. These infrared solutions from KÜBLER are already H₂-compatible and can be flexibly converted to hydrogen in the future.

More about KÜBLER's hydrogen infrared hall heaters

Requirements for the ideal heating system for a workshop

Workshops are not traditional workspaces. They are often high-ceilinged, poorly insulated, and not used continuously. Vehicles come and go. The hall door is open. In such environments, heat works differently—and quickly becomes a question of cost. Two factors are crucial if a heating system is to operate economically and comfortably in the long term: legal and functional requirements.

Legal requirements: GEG & Workplace Directive

Workshops are subject to two types of legal requirements—and both should be taken into account when selecting the right heating system:

The Building Energy Act (GEG) regulates how efficient and climate-friendly new heating systems must be – especially in new buildings. The well-known 65 % rule for renewable energies applies here as a general principle. However, there is a special regulation for halls over 4 m high: anyone who saves at least 40% energy with a new system can comply with the GEG even without a heat pump. This is exactly where KÜBLER comes in – with infrared systems that heat with pinpoint accuracy and are particularly efficient.

The Workplace Directive (ASR A3.5) specifies the minimum temperatures that must be maintained in workplaces, depending on the activity and the level of physical exertion involved. It is crucial that the required temperatures are achieved in a targeted manner without unnecessarily heating the entire hall volume. Infrared heat acts directly in the work area—efficiently and in compliance with regulations.

A simplified overview of typical minimum temperatures according to ASR A3.5:

Workshops are subject to two types of legal requirements—and both should be taken into account when selecting the right heating system:

The Building Energy Act (GEG) regulates how efficient and climate-friendly new heating systems must be – especially in new buildings. The well-known 65 % rule for renewable energies applies here as a general principle. However, there is a special regulation for halls over 4 m high: anyone who saves at least 40% energy with a new system can comply with the GEG even without a heat pump. This is exactly where KÜBLER comes in – with infrared systems that heat with pinpoint accuracy and are particularly efficient.

The Workplace Directive (ASR A3.5) specifies the minimum temperatures that must be maintained in workplaces, depending on the activity and the level of physical exertion involved. It is crucial that the required temperatures are achieved in a targeted manner without unnecessarily heating the entire hall volume. Infrared heat acts directly in the work area—efficiently and in compliance with regulations.

A simplified overview of typical minimum temperatures according to ASR A3.5:

| Hard work | Predominant posture | minimum temperature |

|---|---|---|

| light work | Sitting | 20 °C |

| light work | Standing / Walking | 19 °C |

| average activity | Sitting | 19 °C |

| average activity | Standing / Walking | 17 °C |

| heavy work | Standing / Walking | 12 °C |

Frequently Asked Questions

Frequently asked questions about hall heating systems

Politically promoted, often problematic in practice: heat pumps quickly reach their limits in halls. Properly understood, the GEG leaves room for technological openness—and this is precisely where infrared hall heating systems come into their own.

How does infrared heating work?

Infrared heaters work with heat radiation – similar to the sun. The radiation does not heat the air in the room, but hits bodies, floors, and surfaces directly. The heat is felt where it is needed – in the work area. This reduces energy losses, for example when doors are open, and ensures a consistent feeling of warmth without drafts.

Depending on the system, infrared radiation is generated using (bio)gas, hydrogen, or electricity. Gas-powered heaters usually use long-wave radiation (e.g., dark radiators), while electric devices emit short- to medium-wave radiation. Both variants work precisely in specific zones, react quickly, and are particularly suitable for rooms that are used frequently or irregularly, such as workshops.

Depending on the system, infrared radiation is generated using (bio)gas, hydrogen, or electricity. Gas-powered heaters usually use long-wave radiation (e.g., dark radiators), while electric devices emit short- to medium-wave radiation. Both variants work precisely in specific zones, react quickly, and are particularly suitable for rooms that are used frequently or irregularly, such as workshops.

How quickly is the heat available when I open the workshop in the morning?

Infrared workshop heaters from KÜBLER deliver heat at the touch of a button – exactly where it is needed. This is due to the radiation principle: instead of heating the entire hall, the dark radiators target floors, surfaces, and people. Shortly after switching on, the comfort zone is created in the recreation area – even when outside temperatures are cold. Long heating times, as with water-based or air-based systems, are eliminated. The result: greater efficiency, lower energy consumption, and noticeable comfort from the very first moment.

Can I heat specific areas of the hall?

Yes – that is one of the great strengths of KÜBLER's infrared technology. Each hall heating system can be operated as its own „heat zone.“ Whether individual workstations, assembly areas, or entire sections of the hall: you only heat where work is actually being done. This not only saves energy and costs, but also makes your heating solution particularly flexible. Shift changes, partial use, or seasonal requirements can be accommodated without any effort—an advantage that conventional systems hardly offer.