Dexion is one of the world's leading providers of customized warehouse logistics solutions. The product range of the long-established company extends from innovative pallet racking systems and shelving construction to complete storage solutions, automated, static, dynamic as well as office and archiving solutions. Dexion has been part of the high-performance Gonvarri Material Handling Group network since 2018. At the Laubach site, around 200 employees work on developing highly individualized storage solutions that help their users to be faster, more efficient and more profitable.

The project

The hot air heating system had been in service at Dexion since 1985. However, the performance level of the system was no longer up to date. For this reason, the management had repeatedly considered an energy-efficient refurbishment of the heating system and had already contacted KÜBLER. When the specialist for energy-saving hall heating systems launched the new HeizWerk heating service in 2017, the decision was made. The opportunity to use a modern, energy-efficient and cost-saving infrared heating system without investment and depreciation costs was the deciding factor for Dexion to implement the refurbishment measure before the next heating period.

"For us, HeizWerk was the pragmatic and economical answer to the question of modernizing the hall heating system."

The initial situation

The production halls and warehouses on Dexion's 69,000 m² site in Laubach have been heated with hot air blowers for around 40 years. Originally they were operated with oil, and since 2010 via a local heating network. However, efficiency was noticeably decreasing. In addition, the operation of the system was too costly. Various heating systems were compared. Dexion opted for the energy-efficient infrared heating systems from KÜBLER. Implemented via the new HeizWerk rental model.

The customer requirements

The objectives of the comprehensive heating modernization were clearly defined at Dexion:

- Increasing thermal comfort and thus employee satisfaction.

- The reduction of energy consumption and CO2-emissions.

- No additional costs compared to the old system.

- The option of on-site heating control by Dexion, according to heating zones and shift operation.

- Documentation and reporting of consumption values for quality management and for audits in accordance with ISO 50001 (energy management) and ISO 14001 (environmental management).

Dexion had already clarified the technology issue in advance. Given the building situation at the Laubach site - barely insulated roofs, large surfaces to reflect the heat radiation - infrared technology was the first choice for the decision-makers at Dexion from the outset.

Rent heat - the HeizWerk

HeizWerk is the innovative heating service from KÜBLER. Ideal for new builds and renovations. And perfect for anyone who wants to benefit from the possibilities of modern energy-efficient heating technologies without investment and depreciation costs. For more economy. More heating comfort. And less CO2-emissions.

HeizWerk is a complete all-round carefree service package for hall heating. It includes all services - from the analysis of hall-specific energy flows, planning and engineering of the new system to reliable heating operation - and bundles them into a single product: heat. A very pragmatic rental model. With a number of relevant advantages. The most important ones:

KÜBLER's highly efficient and multi-award-winning heating technologies are supported by the intelligent EMMA management and monitoring system. It ensures a high level of transparency in the heating process - important for identifying and exploiting efficiency potential. And a prerequisite for environmental or energy management audits such as ISO 50001 or DIN 16247.

- No investment and depreciation costs

- Immediately reduced operating costs

- Immediately reduced emission values

- High heating comfort with leading high-efficiency technology

"The rental model has solved our heating problem. And saved us over 45,000 euros."

The solution

Im Rahmen der neuen Wärme-Dienstleistung HeizWerk wurde der Austausch der Warmluftheizung in Halle A durch ein modernes energieeffizientes Infrarot-System umgesetzt. Die Anlage wurde schlüsselfertig und betriebsbereit übergeben.

heating system. 33 devices from the OPTIMA plus 40 infrared heating range with a heat output of 1,320 kW were installed. The heat output of infrared heaters is similar to the heat principle of the sun - the most pleasant heat principle for humans. The heat is transferred between the heat source and the object via infrared, so that it is primarily the room temperature that is heated, not the air. This is a decisive advantage in high hall rooms. This is because no warm air cushions are formed which, for physical reasons, rise below the hall roof and fizzle out there unused. This prevents draughts and dust turbulence from occurring in the first place. And another plus point: infrared radiation can be directed like light and acts quickly where it is used: directly in people's working areas.

Exhaust gas routing. Four collective flue gas systems guide the exhaust air from the heating systems through the wall. The option of bundling the heating exhaust air in one system has advantages over conventional exhaust ducts. First and foremost, the significantly reduced number of wall and roof openings. In addition, the collective flue gas duct provides the basis for waste heat recovery in the system (H.Y.B.R.I.D.1). And thus for up to 15% of additional usable energy, which can be used for hot water preparation (e.g. for office heating, sanitary facilities, domestic hot water or other hot water systems).

System control. To enable Dexion to control the KÜBLER heating system on the customer side, two digital controls from the new CELESTRA line were implemented. The data is transmitted via powerline technology over the normal power grid. The approx. 10 m high hall at Dexion was divided into 10 heating zones, which can be controlled individually depending on the volume of work and heating requirements. CELESTRA has multiple patents. A highly functional, intuitive digital control cockpit. The central lever for adapting system operation to changing requirements and operating at optimum efficiency levels. Up to 20 % additional savings can be generated in this way, and even more depending on the project.

Heat management. Das Monitoren und Analysieren der Anlage im Rahmen der Wärmedienstleistung HeizWerk erfolgt zentral bei KÜBLER über EMMA (Energy Monitoring & Management Application) – das neue Energie- bzw. WärmeManagement-System. Dieses leistungsfähige Tool stellt auch die Verbrauchsanalysen und Dokumentationen bereit, die Dexion für das interne Qualitätsmanagement sowie für die Audits nach ISO 50001 und ISO 14001 benötigt. Übrigens: EMMA ist Bestandteil der innovativen Vernetzungs- und Digitalisierungsstrategie WÄRME 4.0) von KÜBLER.

CELESTRA is a highly functional control cockpit. Patented several times. The central lever for adapting system operation to changing requirements and operating at optimum efficiency levels. Up to 20 % additional savings can be generated in this way, even more depending on the project.

1) Twice awarded for its special energy efficiency: German Sustainability Award 2012 and Rhineland-Palatinate Innovation Award 2012.

2) WÄRME 4.0 - the digital hall heating system. Awarded the Innovation Prize of the State of Rhineland-Palatinate 2018.

Optimization during operation

The operation of the new heating system is digitally monitored and analyzed at KÜBLER. This means that users can be given valuable tips on how to save energy on site to further increase energy efficiency. For example, to optimize switch-on and switch-off times or other operating settings. The analyses can reveal potential savings that go beyond pure heating operation. High energy losses due to long door opening times or leaks in the building envelope, for example. The TorOff plus control module was subsequently installed at Dexion as a fast-acting solution. It switches off the heaters near the doors as soon as they are open, thus helping to avoid unnecessary energy loss. In addition, TorOff plus records the frequency and times of door openings and thus provides important information for optimized usage behaviour by employees.

The results

The new infrared heating system went into operation on schedule in summer 2018. This allowed Dexion to use the full 2018 / 2019 heating period. The results show that it is not just the high-efficiency technology that leads to high savings. Actively working with data and analyses from the EMMA heat management system can also lead to ambitious energy savings - as is the case at Dexion.

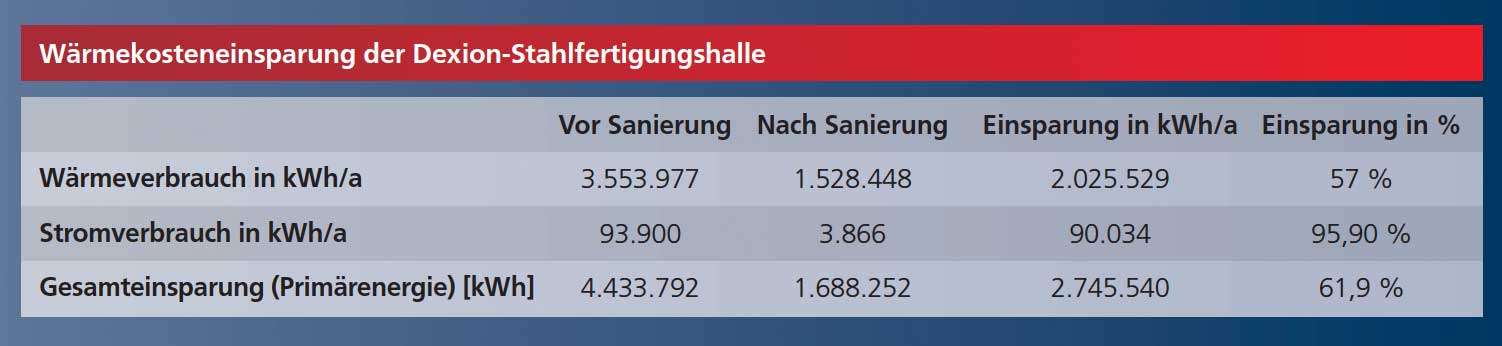

At Dexion, the results have exceeded all expectations: Final energy consumption in the 8,500 m² steel production hall has fallen from 3,553,977 kWh/a to 1,528,448 kWh/a, a reduction of 43 %. In the same period, the electricity consumption of the heating-related components was reduced by almost 96 %. Overall, primary energy consumption was reduced to less than 40 % - 61.9 % of energy was saved. The decision to modernize the heating system with HeizWerk has also paid off financially for Dexion: The warehouse logistics specialist recorded cost savings of over €45,000 in the very first year of operation. And this without having to make any investments of its own.

"The modernization of our hall heating system was a complete success."

Interview

Hans Fuhrmann is Director of Production at Dexion GmbH. He was personally involved in the energy refurbishment project in Laubach, from the decision to opt for HeizWerk to the technical planning and system operation. He spoke to our editorial team about his experiences and impressions of the new infrared heating system after the first heating period.

Dexion had been preparing the heating modernization for a long time. How did the decision for KÜBLER come about?

My motto "Look at Dacia and look at Mercedes - then you'll know the relevant decision parameters" has proved its worth. We initially compared various manufacturers. However, it quickly became clear to us that we were leaning towards Mercedes, i.e. KÜBLER. These solutions are simply the best in terms of technology and energy efficiency. But it was also clear that we couldn't get the budget free. Ultimately, the decisive factor for us was that we were able to rent the system. Without the rental concept, we would not have implemented the measure.

What was so appealing about the new rental model for Dexion?

First and foremost, the fact that we had no capital expenditure. And then the guarantee that we would not have any additional costs despite the increased heat output. But the clear and flexible contract was also convincing. We were able to structure the agreements in important points in such a way that they fit in with our group.

The old system was still functional. Didn't you take an unnecessary risk with the modernization?

We knew that KÜBLER stands for quality. And when you see the managing director in person under the roof of the hall during the as-built survey, you can be sure that someone knows what they are doing. This and, of course, the detailed discussions and technical explanations have shown competence and given us security: When KÜBLER makes promises, they are kept.

Were there no surprises in the course of the major project?

We supported the modernization from planning to implementation with internal expertise and knew that the technology was right. The implementation phase was also well coordinated and went extremely well despite the fact that production operations continued. I had doubts about the savings calculation. I assumed a +/-zero difference in the first year. I was really surprised and delighted that we immediately achieved savings of almost 62 %.

You have the heating operation monitored by KÜBLER and still control it yourself. How do you do this and what is the reason for it?

The control system gives us the opportunity to respond much more flexibly and better to current conditions, e.g. shift scheduling. The control system has a wide range of setting options that are very easy to make. It is important for our energy management to report the consumption values - for internal quality management and because we are audited in accordance with ISO 50001 and ISO 14001. I pull the data from the system for this. Per heating zone and, if necessary, per appliance - that's great, we couldn't separate them at all before. A big advantage is that the system is analyzed at the KÜBLER headquarters. This has uncovered some interesting potential savings that we will exploit.

How did your employees deal with the changeover?

It was too cold for some at first. We had changed the machine positions but not adjusted the lighting. It took us a few weeks to optimize the start times, settings and sensor positions so that everyone felt comfortable. But both the employees and the works council have now literally warmed to the new system.

So the issue of heating will continue to occupy you?

Yes, absolutely. As far as the control system is concerned, we will go into even more depth. Where can we optimize running times? How can we play with start times? How can we save even more? The door problem, which KÜBLER pointed out to us, certainly still offers a lot of potential. We will tackle this with new roller shutters. We therefore expect the next heating period to bring even better savings. And the lighting in the hall will certainly be an issue again, because we are planning to move machines again. We are also currently discussing a possible expansion of the system in another production hall.

What is your conclusion after the first heating period?

The renovation of the hall heating system was a complete success. We would not have been able to meet the requirements for a uniform working temperature in our hall situation and constantly open doors without these systems. We now have clean energy in the hall. There is no air turbulence and the dust load is significantly lower. The economic efficiency is absolutely given. 62 % savings speak for themselves.

Would you recommend KÜBLER to others? And if so, to whom?

Anyone who deals with hall heating is in good hands with KÜBLER. This starts with the high level of expertise in consulting, the technical solution portfolio and extends to the professionalism in implementation. For me, the savings achieved also fall under the heading of competence. The rental model should also be very interesting for other companies, just as it is for us. The demand for innovative efficiency technology is high. But the budget is not always free. Or there are other reasons for not wanting to invest. If halls are rented, for example. Or are only to be used for a limited period of time.

"Now we have clean energy in the hall. Without draughts. And the dust pollution is significantly lower."

"Anyone who deals with hall heating is in good hands with KÜBLER."

The KÜBLER Group

KÜBLER GmbH is an internationally active group of companies. Our core business is the development and production of highly efficient premium technologies for energy-saving hall heating. With an exceptionally wide range of products for almost all types of halls and room environments. KÜBLER is regarded as a pioneer and innovation leader in modern infrared heating technology.

Our products and development work regularly receive awards. The national and international awards include the Federal Prize for Outstanding Innovative Achievements from the Ministry of Economic Affairs, the Bavarian State Prize and the German Sustainability Award. KÜBLER received the highest German award for sustainable entrepreneurship in the category "Germany's most sustainable product" for the special energy efficiency of the H.Y.B.R.I.D. system.

In 2018, KÜBLER was honored for the third time with the Innovation Award of the State of Rhineland-Palatinate. Awarded for the innovative WÄRME 4.0 strategy - the digital hall heating system. Founded in 1989, the group of companies employs over 120 people and is one of the leading companies in the industry in Europe with locations in Ludwigshafen, Dresden, Hagen, Hamburg, Prague (Czech Republic), Fegyvernek (Hungary), numerous foreign agencies and a nationwide service network.