The right waste heat recovery for your business - how to convert waste heat into energy in just a few steps

Only around half of German companies know how waste heat recovery works properly and what potential it holds - according to the dena in their Publication on waste heat recovery as part of the Initiative Energy efficiency. This means that an estimated 226 TWh of usable heat goes unused every year. That is 36 % of the energy used by the entire manufacturing industry. Clearly, this costs companies an enormous amount of money, but at the same time the unused waste heat has a negative impact on the environment. Around 60 million tons of the greenhouse gas CO2 are unnecessarily evaporated into the atmosphere every year. In view of rising energy costs and climate protection targets, companies simply can no longer afford to do this.

How can you benefit from intelligent waste heat recovery? Find out in this article.

Start your smart waste heat utilization by identifying waste heat sources

Depending on the type of operation, waste heat is generated in a wide variety of places. Ovens, machines, cooling systems and uninsulated pipes of hot air heating systems are probably the classics. Get to the bottom of the causes of wasted waste heat by thoroughly analyzing and evaluating energy consumption throughout the company. The next step is to avoid or at least reduce unnecessary waste heat by optimizing processes. The following questions will help you do this:

- Can you avoid idle time?

- Are all systems/processes really running efficiently, or is there still room for improvement here and there?

- Are some processes perhaps oversized?

- Are there any heating or cooling phases that would not be necessary in practice?

- Do you maintain your machines and systems regularly?

- Are you insulating sufficiently?

With a comprehensive analysis, you can already save a lot of waste heat. For the rest, you should rely on intelligent waste heat recovery.

Industrial waste heat recovery - simply pass on the waste heat

The practical thing about intelligent waste heat utilization is that you can use waste heat in a variety of ways to increase energy efficiency in your company. For example, if you don't want to use the waste heat from your company yourself, others will be happy to do so. For example, district heating networks that cover the heating requirements of private households or public buildings, or even neighboring companies. Of course, the necessary infrastructure must be in place or created for this - on the other hand, a certain amount of heat loss during transportation must be taken into account.

The correct use of waste heat is also important for cooling

Do you have enough heat, but would you like a little more cooling and electricity? Then it's best to use waste heat for exactly that. With chillers, steam processes and ORC systems, waste heat can also be used to generate cooling or electricity - so the right use of waste heat can also bring you benefits in summer.

... and is also ideal for other processes

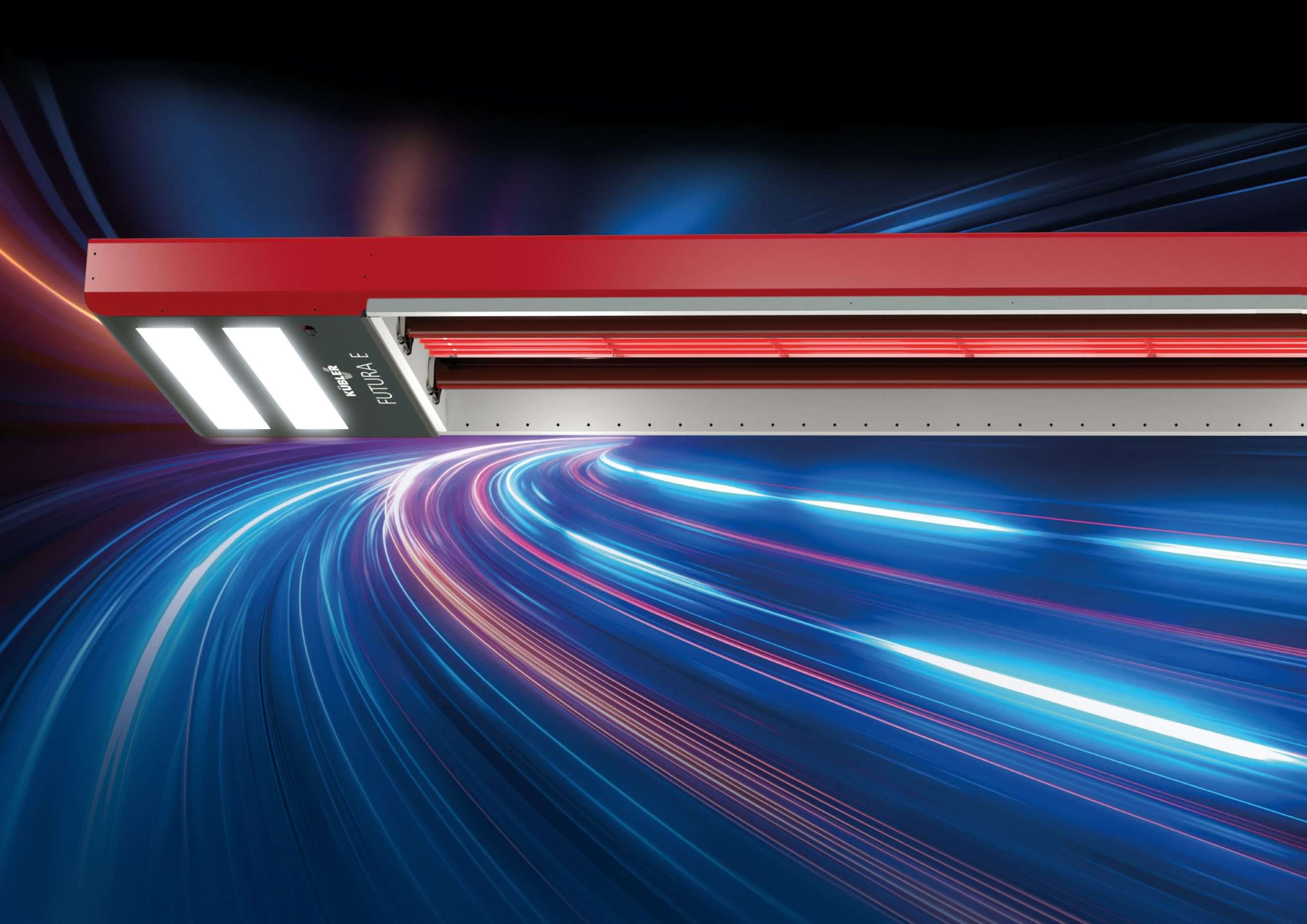

"Hybrid heating" is an important keyword here. This is because the correct use of waste heat can also play an important role in the preparation of hot water or the heating of rooms. While this variant of waste heat utilization has already established itself in many private households, it is now also suitable for heating hall buildings. This is because, thanks to inefficient technology and a lack of insulation, they have a reputation for consuming a lot of energy.

Numerous heat flows in the building, such as process heat or waste heat from compressors, can be harnessed if you integrate them into infrared heating systems that have been combined with a residual heat utilization system. You can even integrate renewable energies such as solar thermal energy to efficiently support heat generation in your company. In this way, you benefit from the clever use of waste heat in many essential processes in your company.

The bottom line: the right use of waste heat and hybrid heating are worthwhile - especially from a financial perspective

Anyone who integrates intelligent waste heat recovery in their company and therefore has to use less energy to generate heat saves money. That is crystal clear. How this translates into concrete figures depends on various factors, such as

- the type and size of your company,

- the volume to be heated,

- the number of processes that generate waste heat and

- the Heatingthat you use.

At a production plant in Rhineland-Palatinate, for example, the recovered energy completely covers the heating requirements of the 1,200 m² of office space. Another company saved with efficient waste heat utilization 9,000 euros per year - and some drinking water that was previously drained off almost unused.

The Federal Ministry for Economic Affairs and Energy is also concerned about the efficient use of waste heat in view of the figures mentioned above. Entrepreneurs can therefore not only save energy costs with greater energy efficiency, but can also benefit from funding programs. The "Federal funding for energy efficiency in the economy" package offers several options for this.

Conclusion: Optimization potential in waste heat recovery can be found in a wide variety of places

Hall modernization, proper insulation, highly efficient Heating systems and waste heat recovery: there are many ways to increase the energy efficiency of your business and reduce costs. Feel free to contact us and let us advise you on the optimal use of waste heat. We can help you find out how you can use the previously "wasted" waste heat from your processes to good effect. We look forward to hearing from you and accompanying you on the path to optimal waste heat utilization.

-

Back in July 2022, the BMWK published its concept paper on the amendment to the Building Energy Act (GEG), thereby not only causing hopeless uncertainty, but also preventing investment in necessary energy-efficient renovations. First things first: the amendment has not yet been passed - and it is questionable whether it will actually be passed 1:1. Because if you trust Struck's law, a law does not usually leave parliament in the form in which it was introduced.

-

What is probably the most effective lever against the gas crisis, price pressure and dependence on Russia at the moment? The answer: consuming less energy. The German government is of this opinion and is calling for energy savings in a large-scale campaign - supported by industry and associations. This goal can be achieved. When it comes to the large halls of industrial and commercial enterprises, it is even easier and quicker than expected.

-

Fair.AIdH - ideal heating systems for special buildings Halls have different heating requirements than office or other multi-storey buildings. As a rule, "normal" hot water heating systems inevitably fail due to the enormous room heights and dimensions: they consume an unreasonable amount of energy, offer little flexibility and thermal comfort, can hardly be controlled variably, heat hall ceilings instead of work areas, are often simply uneconomical and [...]

-

In 2021, the new CO2-tax came into force. It is intended to help Germany achieve its climate protection targets. Read on to find out what this means for your company in terms of costs and what you should do now!