Innovations for the energy transition

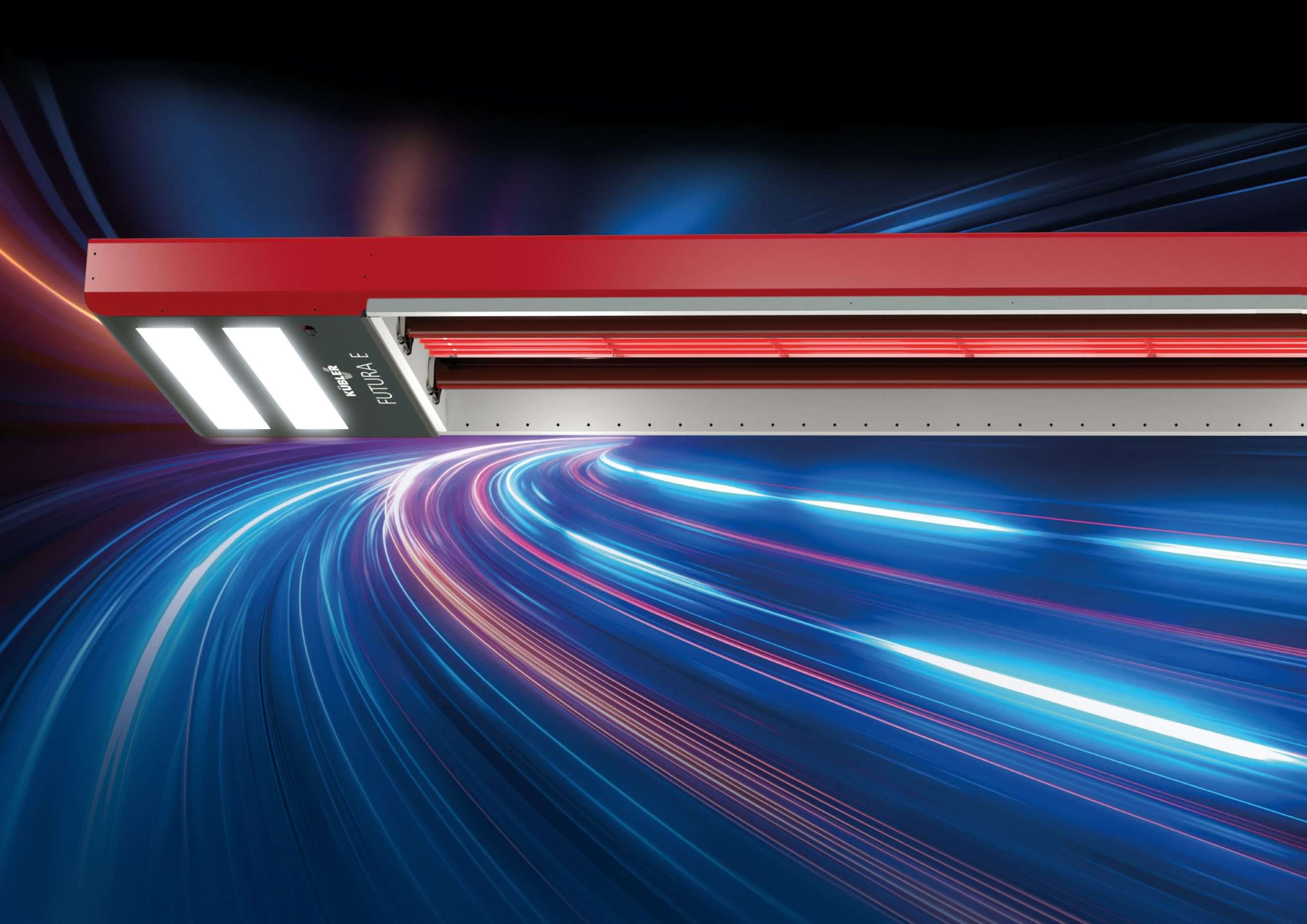

KÜBLER hall heating systems

High cost-effectiveness, a pleasant indoor climate and sustainable energy efficiency: KÜBLER infrared hall heaters are made for the special and demanding heating requirements in tall buildings. Suitable for every type of hall, for every usage profile and especially for your individual needs. Discover KÜBLER's dark radiant heaters in the high-efficiency classes.

Infrared hall heaters