With Element-System, Bohnacker Systeme GmbH is the number 1 in the field of shelving and storage systems for end users. From its headquarters in Rottenacker, the company, founded in 1954, coordinates business activities in over 60 countries on all continents and guarantees the supply of customized solutions to its customers. Every year, steel twice the weight of the Eiffel Tower is processed into beams, rails, shelves, furniture legs and shelving at the production facilities in Germany, Hungary and China. Bohnacker Systeme GmbH generates an annual turnover of 60 million euros and employs over 500 people worldwide.

A new decentralized heating system has been in use at Bohnacker Systeme GmbH since December 2008. The concept from hall heating specialist KÜBLER, which is specially tailored to the complex building constructions at the main site in Rottenacker, not only impresses with its excellent efficiency levels, but also with an innovative hybrid overall solution, which was installed as a pilot project in Hall 1. This integrated system consisting of infrared heating, control and the newly developed residual heat utilization O.P.U.S.X combines infrared heating technology with conventional hydraulic hot water heating. The complete refurbishment of the heating system in the production plant with a total of 18 halls improves efficiency and makes a decisive contribution to environmental protection and sustainability.

The initial situation

For more than 30 years, a classic hot air heating system has been heating the production plant of Bohnacker Systeme GmbH. The building complex of 18 production halls with different usage profiles ranging from storage, order picking and packaging to production was heated by two boilers, each with 3,500 kW, via a central boiler house. This made it difficult to control the heating in the individual halls according to demand. With a total floor area of 23,265 m2 and hall heights of 4 to 13 meters, consumption was correspondingly high.

The requirements

Saving as much primary energy as possible was the main requirement for the heating renovation in the production plant when the comprehensive project was commissioned on October 20, 2008. At the same time, the new heating system had to be decentralized, take into account the existing hall structures, be able to be implemented without major conversion work and integrate the existing hot water system for office heating. The aim was to put the new system into operation before Christmas - on the one hand to ensure heating during the holidays, but also to make the most of the new heating period. An ambitious undertaking - not only because of the complexity of the project, in which a complete existing pump and hot water system with all piping was to be integrated into the new heating system. The logistics were also a particular challenge. The interconnected hall complexes meant long distances, if only to transport the components to be installed on site. Assembly was carried out in two shifts into the night during ongoing operations. At times, five trades were working simultaneously.

Refurbishment measure 1: Decentralization of the hall heating system

The refurbishment concept for Bohnacker Systeme GmbH included the complete replacement of the outdated hot-air heating system with a modern, energy-saving infrared heating system. The efficient heating technology from KÜBLER is now in operation in Rottenacker. The system components in detail:

Infrared heaters. A total of 123 energy-saving infrared devices were installed. Tailored to the individual usage profile and heating requirements in each of the 18 halls, the overall concept from KÜBLER combines different types of devices: 63 devices from the Optima high-performance system with an output of 25 or 38 kW, 56 NRV multi-burner systems with an output of 24 to 32 kW and four AR devices with 13 kW each. The design of the overall system ensures even, dust-free and draught-free heat distribution with short heat-up times and high energy efficiency for different room heights from less than 4 m to 13 m.

control system. Seven R.O.S.S.Y® systems now ensure convenient and efficient operation of the complex heating system in Rottenacker. A total of 34 individual heating zones have been defined, which can be controlled individually in order to respond to different temperature requirements and to define the switch-on and switch-off points at night, at weekends or on public holidays precisely as required. The resource-optimizing control system R.O.S.S.Y® is directly connected to the KÜBLER control station at the company headquarters in Ludwigshafen. This ensures transparency of all relevant operating and consumption data at all times and guarantees maximum efficiency of the entire system by reducing operating costs for primary energy, maintenance and spare parts.

Residual heat utilization. The 432 kW system consisting of infrared heating and heating control was supplemented in Hall 1 on a trial basis by an innovation from KÜBLER: the O.P.U.S.X. heat exchanger. This innovative system for residual heat utilization can use the energy contained in the exhaust gas from hall heating systems for hydraulic hot water preparation and is the basis for the new and most efficient heating concept from KÜBLER to date: the hybrid system H.Y.B.R.I.D.

Refurbishment measure 2: Decentralization of the pump hot water system for office heating

The existing pump hot water system was completely decentralized for heating the office buildings. Five efficient gas condensing boilers and a boiler with a total output of 833 kW now replace the two old 3,500 kW boilers and the central boiler house. They ensure short distances and reduced energy consumption.

The existing peripherals were largely used, but new pumps and pipes were integrated. Whereas previously there was only one complex pump system for supplying the individual sub-distributors, this was also decentralized in order to be able to control individual heating processes in a more targeted manner.

Results of heating system refurbishment

After the contract was awarded on October 20, 2008, installation began on October 24. The new hall heating system was put into operation before Christmas. On 15 February 2009, the modernized infrared heating system, including the state-of-the-art pump hot water heating system, was handed over to the customer. The entire installation was carried out without interrupting production during ongoing operations. The new system was put into operation at the same time as the old system was shut down. A side effect of the energy-saving infrared heat for Bohnacker Systeme GmbH is the storage of coils: the humidity is reduced by the infrared heaters in such a way that condensation is reliably avoided.

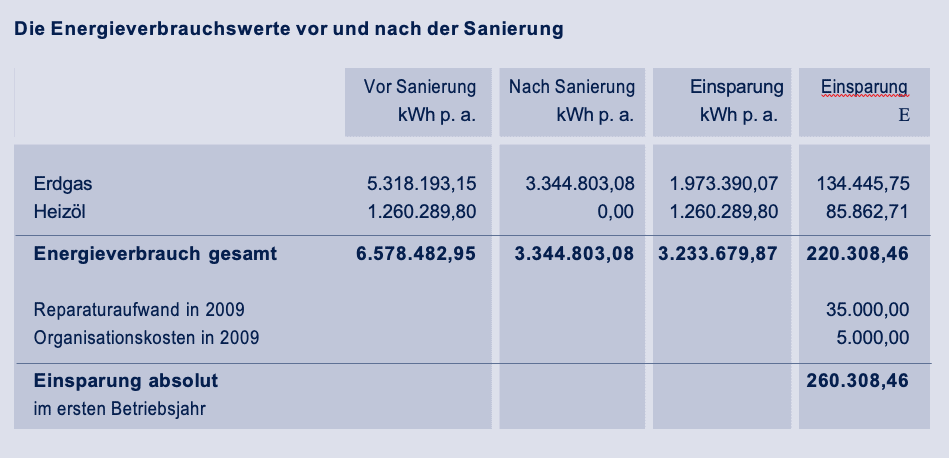

However, the main aim of the refurbishment was to achieve significant savings in primary energy consumption. Around 40 % energy savings were forecast and guaranteed. After the first few months of operation, it was clear that the expectations had been fulfilled. Instead of an average primary energy consumption of up to 6,500,000 kWh p.a., the annual consumption after refurbishment is now only 3,344,000 kWh. At a kWh price of around 0.07 euros, this results in annual cost savings of over 220,000 euros. This corresponds to around 49 %. In addition, considerable expenses of around 40,000 euros were saved, which would have been incurred in 2009 for repairs to the old system. This brings the total savings in the first year of operation to around 260,000 euros.

However, other expenses were also reduced:

- Savings on personnel costs for operating the boiler house

- Savings on maintenance and servicing costs

- Saving costs for operating materials

- Gaining new usable space by decommissioning the old boiler house

The investment of around 700,000 euros will have paid for itself in around three years for Bohnacker Systeme GmbH.

Results

The results are based on the actual values for the first months of operation from December 2008 to April 2009. Adjusted for the different cold periods in the months of October to December and January to April, the total savings in the first year of operation are calculated from these values at around 220,000 euros for primary energy consumption and a further 40,000 euros for necessary repairs to the old hot-air heating system.

Results Residual heat utilization At Bohnacker Systeme GmbH, O.P.U.S.X in Hall 1 fed 69 kW of power into the hot water system via a 3,000 l buffer tank as required at peak times. This corresponds to around 8 percent of the output of the entire modernized pump hot water system.

Customer interview with Fernando Gomes-Anjo, Bohnacker Systeme GmbH

Fernando Gomes-Anjo is technical production manager and member of the management board of Bohnacker Systeme GmbH. In order to completely modernize the heating system in the production plant in Baden-Württemberg, he opted for the most modern solution that KÜBLER has to offer: H.Y.B.R.I.D. - an overall concept comprising heating, control and residual heat utilization. Our editorial team spoke to him in Rottenacker about planning, installation and initial operating experience.

You had several concepts from different heating manufacturers presented to you in a competition. What factors were decisive in finally awarding the contract to KÜBLER GmbH?

Overall, KÜBLER GmbH impressed us with a technically detailed application and its customized overall concept. The decisive factor for awarding the contract was, on the one hand, that KÜBLER GmbH was able to offer us a solution that was specially tailored to our hall structures and did not require any major conversion work. Secondly, I visited a company with almost identical halls that had also installed KÜBLER equipment. There I was fascinated by the efficiency of these units, and it was the efficiency factor that ultimately convinced me the most.

What requirements did you place on your new heating system in the run-up to the modernization? Our most important requirement when refurbishing the production plant was to achieve the highest possible savings potential compared to the poor efficiency of the old air circulation system. The new heating system had to integrate the supply to the office buildings and be decentralized in order to minimize losses through short distances. The control system had to be easy to operate and easily accessible. KÜBLER fulfilled all these requirements perfectly and also ensured rapid implementation without any production downtime.

And what advantages does the use of infrared technology offer you compared to your previous system?

Not only do the KÜBLER appliances enable us to recoup the investment costs after just three years, but thanks to the infrared technology, CO2-emissions by around 570 tons per year. As environmental protection and sustainability are firmly anchored in our company philosophy, this is also an important plus point. Another decisive advantage, particularly when storing metal parts, is that the appliances are dust and airflow-free and the dry room air prevents condensation.

The complete modernization took place during ongoing operations. Were there any disruptions during the installation?

No, not at all. There was no loss of production and the new system was put into operation as planned when the old one was shut down. The entire implementation was extremely professional, and the plan to convert the halls with the greatest savings potential first was adhered to exactly to our satisfaction. We received detailed advice from KÜBLER in advance and were given a precise description of the system and controls, so that we were able to work well with the system right from the start.

And how have the employees reacted to the changes? Has there already been any feedback from them?

The opinions here are consistently positive. Everyone unanimously emphasizes the much more pleasant warmth, which does not escape immediately if a window is left open in the halls. In particular, the heat stored in the floors, which is emitted from below, is similar to that of underfloor heating and is perceived by everyone as much more pleasant. Many also say that it gets warm much faster now and that the new heating systems are much more efficient.

About KÜBLER

With its innovative infrared systems, KÜBLER GmbH develops and sells the most modern and economical technology for heating large spaces and today, as a complete supplier of turnkey solutions, provides the comprehensive product range for different types of halls and room environments. KÜBLER has made a significant contribution to the breakthrough of modern infrared technology. The company is regarded as an innovation leader in the industry and regularly receives awards for its innovative achievements. National and international awards include Industrial Heater of the Year 1996, Federal Prize for Outstanding Innovative Achievement 2004, Company of the Year in Ludwigshafen, finalist for Entrepreneur of the Year 2005, Bavarian State Prize 2006, Grand Prize for Medium-Sized Enterprises 2008 and the Rhineland-Palatinate Innovation Prize 2008. KÜBLER has registered six patents and twelve trademarks. Founded in 1989, the company employs around 100 people and has branches in Ludwigshafen, Dresden, the Czech Republic and Hungary.