Heating with heavily polluted hall air

Infrared-based hall heating systems offer a proven solution here. This is because their radiant heat ensures a good indoor climate - without draughts or dust turbulence. This is an important health-related benefit, especially for dust-intensive work, such as metalworking or metalworking shops, because the hall atmosphere is not additionally polluted.

A leading concrete plant in Austria also appreciates another advantage: "A hall heating system that runs trouble-free in our dust-intensive production - that's what convinced us the most!" The durability of the infrared devices pays off, especially in a highly polluted atmosphere. Despite the heavy contamination, the hall heaters have been running trouble-free for many years thanks to their robust design.

Incidentally, infrared indoor heating systems are also interesting for companies from an economic and ecological point of view. This is because they often consume only a fraction of the energy of other heating systems. And that pays off. Thanks to their high energy efficiency, infrared hall heating systems can reduce costs by up to 70 % compared to conventional systems. Infrared hall heaters therefore pay for themselves in a short time.

If you would like to find out more about the dust-free and draught-free heating of hall buildings, simply contact us or read the full report here.

By the way: the next Hot tip around the topic Hall building & energy efficiency will be revealed in a week's time.

-

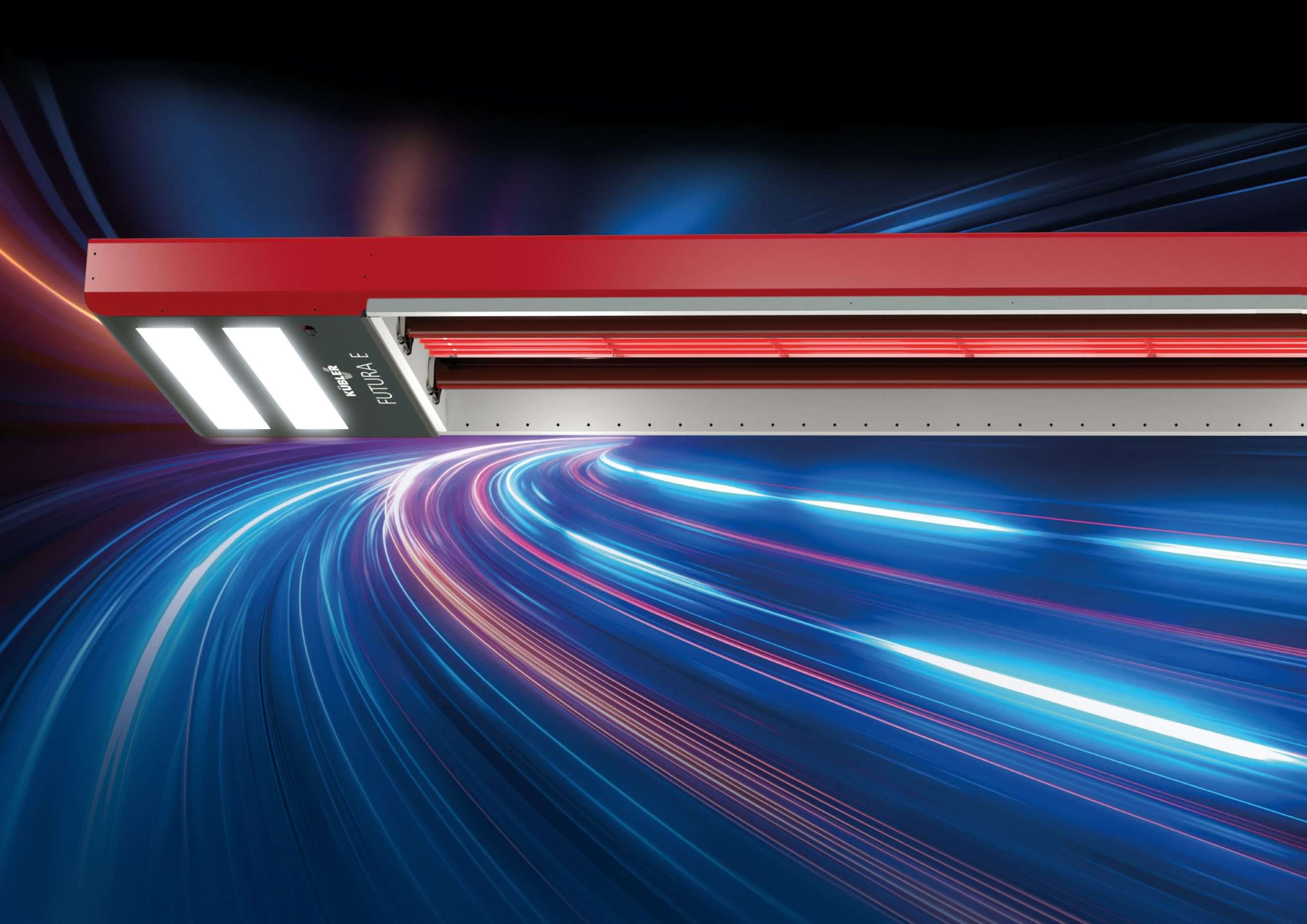

The Federal Ministry for Economic Affairs and Climate Protection has been honoring the commitment of industry and research to climate and environmental protection for many years with the IKU - the German Innovation Award for Climate and the Environment. The 21 nominees include many big names as well as a medium-sized company: KÜBLER GmbH from Ludwigshafen. It specializes in the development of energy-saving hall heating systems and entered the competition with HeizWerk, a smart solution package for industry. Behind this is nothing less than a clever concept for energy-efficient refurbishment in production, storage and other hall buildings without the need for capital expenditure.

-

Nobody thinks about the hall heating when the sun is blazing, the asphalt is glowing and everyone is grateful for the slightest cooling. Or do they? Because anyone who looks ahead knows that summertime is maintenance time. So if you want to start the winter safely with your production halls or warehouses, it's good to be prepared. After all, the next heating period is often around the corner sooner than you think, which raises the question: is your hall heating system fit for the next season?

-

Whether concert fans, art lovers or party enthusiasts: the room temperature also determines the success of events. How hosts ensure a comfortable climate in event halls and exhibition rooms with hall heaters.

-

"Heating with the windows open" in private households is like "heating with the doors open" in production halls and warehouses. It's great if you can afford this in industry and commerce because production and business are obviously running - unfortunately, this is not a matter of course for many companies in times of coronavirus.