New hall heating - zero investment

- Ecologically through significant reduction of CO2-emissions

- KÜBLER already fulfills the CO2-2030 targets (Federal Climate Protection Plan)

- Economical due to significant reduction in heating costs

- No investment costs and depreciation in new heating systems

- No costs for personnel and maintenance

- With state-of-the-art infrared heating technology 62 % of primary energy and 457 tons of CO2 p.a. and achieve a profit of EUR 45,000 (HeizWerk project by Dexion, Laubach)

Ludwigshafen. Tens of thousands of the approximately 420,000 industrial and large halls in Germany are equipped with technically outdated heating systems that unnecessarily pollute the environment with many hundreds of thousands of tons of CO2 burden. Energy-efficient refurbishment of these halls would also generate potential cost savings in the three-digit million range. The reason: many companies shy away from the investment costs and depreciation as long as the old heating system is still doing its job. But this does not have to be the case. How industry can not only save many tons of CO2 The new, ecologically and economically innovative HeizWerk product from KÜBLER GmbH Ludwigshafen for heating industrial and large halls demonstrates that it is not only possible to save energy, but also to make a profit. The company, which has been awarded the German Sustainability Award, among others, equips the halls with the latest and most efficient KÜBLER infrared heating technology - a key technology without which the climate protection targets in halls would be difficult to achieve and which today already meets the CO2-reductions have been achieved. The fixed rental price also includes operating and maintenance management. Companies not only save on investment costs for new heating systems and ancillary costs such as personnel and maintenance; thanks to sustainable infrared key technology, HeizWerk costs are generally even lower than the total annual costs of the previous old heating systems. One of the first HeizWerk projects, an 8,500 m² hall complex, showed total savings of 61.9 % of primary energy after 12 months, which equates to a reduction of 457.5 tons of CO2 corresponds to. After deducting the HeizWerk annual invoice, the hall operator was left with a profit of EUR 45,000 in the income statement.

HEIZWERK SOLVES THE INVESTMENT BACKLOG FOR HALL HEATING SYSTEMS

Replacing outdated, inefficient heating systems in industrial and other halls was previously only possible by purchasing a new system, which entailed high investments. "It is understandable that companies focus their investment programmes primarily on optimizing production and processes, rather than on state-of-the-art heating systems in their production halls," says Thomas Kübler, founder and CEO of KÜBLER HeizWerk GmbH in Ludwigshafen. "In addition, larger investments with depreciation periods do not fit into the financial planning of many companies, especially when the economy is slowing down." And the CO2-reductions are then no longer the primary focus. Thomas Kübler: "Over a fifth of CO2-emissions in Germany are generated in the industrial/commercial sectors, and we can no longer trivialize this. Energy efficiency has always been part of KÜBLER's DNA, and we are now expanding this with a new dimension of cost efficiency in our HeizWerk product." Thomas Kübler and his team of engineers have worked intensively on this task and redefined ecology and economy for heating systems in industrial and other hall buildings. Thomas Kübler: "In our experience, HeizWerk is the simplest, most economical and most climate-friendly system solution for reducing the investment backlog in the energy-efficient refurbishment of large-capacity heating systems in halls, which are still being replaced by uneconomical old systems with high CO2-emissions."

HEIZWERK PROVES: YOU CAN EVEN SAVE MONEY WITH KÜBLER CLIMATE PROTECTION

HeizWerk is a new service offering with a "360 degree carefree package". It includes all services from the analysis of hall-specific energy flows, planning, engineering and the installation of state-of-the-art, energy-saving KÜBLER infrared key technology to complete operational management. The companies have no investments, no depreciation, no operating expenses - they only pay for the energy consumption and the agreed system rental. The bottom line is this: Operators save significant sums of money per year, as the first model plants are now proving. What's more, they have an ecological high-tech product for the long term, as KÜBLER infrared heating systems already fall below the CO2-reductions of 55 % (1990: 100 %), which of course also has a positive effect on future CO2-price of initially 10 euros per tonne of emissions*.

COMPANY DEXION: "HEATING PLANT A COMPLETE SUCCESS!"

Dexion is the world's leading specialist for warehouse logistics solutions, based in Laubach, Hesse, and was one of the first companies to choose HeizWerk from KÜBLER. The opportunity to use an energy-efficient, environmentally friendly and cost-saving infrared heating system without having to invest and depreciate it was the deciding factor for Dexion to implement the refurbishment measure immediately. After more than a year of operation, Hans Fuhrmann, Director of Production, draws an extremely positive conclusion: "HeizWerk is a complete success for us. The results of the first year of operation have exceeded all expectations. Together with KÜBLER experts, however, we are already working on further efficiency optimizations." The heat consumption in the Dexion steel production hall has been reduced by 57 %, while the electricity consumption of the heating-related components has been reduced by almost 96 %. In total, almost 62 % of primary energy was saved, which corresponds to a reduction of 457.5 tons of CO2 corresponds. But the result is not only impressive on the ecological side: after deducting the costs for the heat requirement and the rent for operating the system, the P&L showed a profit of EUR 45,000. "For us, HeizWerk is the pragmatic and economical answer to the alternative of renewing our previous hall heating system at investment cost," concludes Hans Fuhrmann. HeizWerk was thus also able to fulfill another of KÜBLER's forecasts: The annual costs for rent and system operation are below the total costs of the old heating system.

THE "360 DEGREE CAREFREE PACKAGE" FROM HEIZWERK FOR DEXION

KÜBLER bundled its highly efficient infrared systems for large-capacity halls, the complete digitalization of the heating process (WÄRME 4.0) and its expertise in engineering and digital system operation into a "360 degree carefree service package". Infrared heaters from the KÜBLER OPTIMA plus high-performance line were installed at Dexion. They ensure a comfortable and clean working environment in the 8,500 m² steel production hall. The infrared heat transfer does not heat the air in the hall, but primarily the room air and all objects are heated moderately to 20 °C. This is extremely effective, fast and clean. This is extremely effective, fast and can also be easily controlled in terms of time and space. This heat transfer does not produce any warm air that could cause draughts or dust turbulence. This is also the decisive advantage for the efficiency of infrared heat in high hall spaces. This is because no warm air cushion is formed by the heated and therefore lighter air, which could flow under the hall roof and largely fizzle out unused. KÜBLER makes consistent use of physical and digital possibilities for the benefit of the operator. Auxiliary energies such as those previously used for pumps and fans are almost completely eliminated. Thanks to this efficiency advantage, a total of almost 62 % primary energy savings could be realized at Dexion.

INTELLIGENT, DIGITALIZED CONTROL TECHNOLOGY MAKES FURTHER SAVINGS POTENTIAL AVAILABLE

The monitoring, i.e. the permanent supervision of the new heating system, is carried out by KÜBLER - via the online energy and heat management system EMMA This name stands for Energy Monitoring & Management Application. The powerful online control system also provides the consumption analyses and documentation that Dexion needs for internal quality management and for audits in accordance with ISO 50001 and ISO 14001. The transparency provided by the EMMA energy management system has enormous advantages in day-to-day operations and has already revealed further savings potential. For example, KÜBLER experts were able to provide Dexion with important savings tips for regulating the switch-on and switch-off times. Further relevant savings potential was also uncovered in areas that go beyond pure heating operation. In Laubach, these were high energy losses due to excessively long door opening times - a problem that exists in many production halls and warehouses and can be controlled by specially developed KÜBLER software modules. Dexion wanted to take over the actual control of the system itself. Two digital control systems from the new and patented KÜBLER CELESTRA line were installed especially for this purpose. The production hall is divided into 10 heating zones. These can now be individually controlled and regulated in a very simple and self-explanatory manner, depending on the shift operation and heat requirement. For Dexion, this offers unprecedented flexibility to adapt the heating process to different workloads and to be able to intervene at any time. Dexion: "We would not have been able to meet the heating comfort requirements of our hall situation any other way."

-

The Großer Preis des Mittelstandes is one of the special awards that KÜBLER has already received. The specialist for energy-efficient hall heating technologies has also already been recognized with the coveted badge of honour. For KÜBLER, this nomination is about the last two opportunities to go one better for Germany's most coveted business award: to be named Premier or Premier Finalist in the Grand Prix for Small and Medium-Sized Enterprises.

-

Food. Climate protection is a hot topic - and not just since Greta Thunberg. Hall heating specialist and efficiency expert KÜBLER will be demonstrating the immense energy and CO2 savings potential that can be achieved in the heating of hall buildings alone. It will be presenting its high-efficiency solutions at SHK Essen from March 10-13.

-

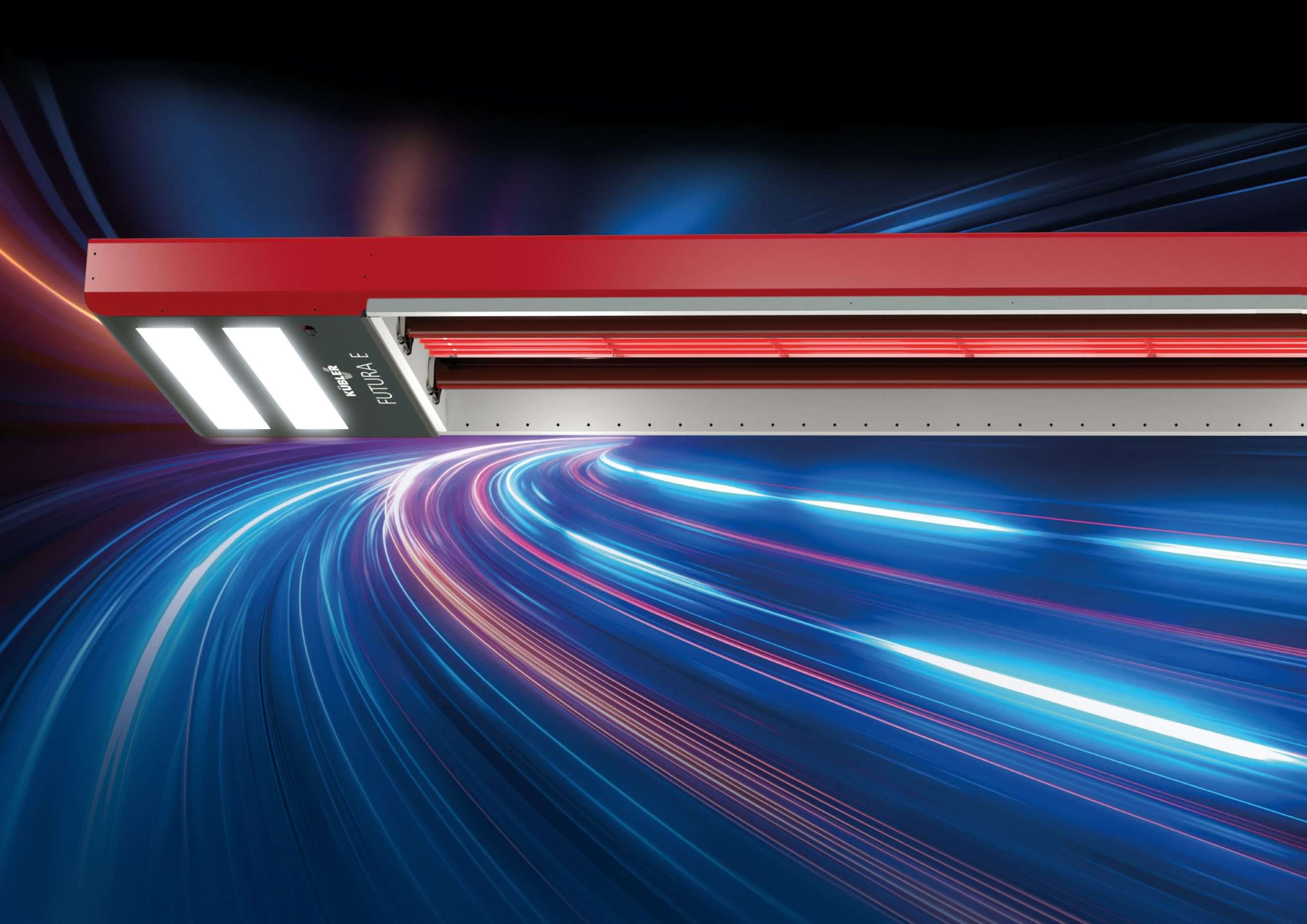

The FUTURA multi-energy infrared heating system from hall heating expert KÜBLER has been nominated for the German Innovation Award. As one of the products, technologies and services that break new, innovative ground and offer solutions that stand out due to their added value for users and the environment.

-

Gas is decentralized, flexible, can be stored efficiently and is inexpensive. The energy source is a guarantee for the success of the energy transition. Ten associations from the gas industry have joined forces and formulated an appeal for the climate protection plan, explaining why gas as an energy source can already achieve significant CO2 savings cost-effectively today.