Heating with perspective

HEATING WITH PERSPECTIVE

Full transparency in the heating process

"If you want to control your energy consumption to the ideal level, you need information. And the right tools," says Thomas Kübler, Managing Partner and founder of KÜBLER GmbH. The company specializes in the development of highly efficient hall heating solutions and is considered the technology leader in this segment. With the EMMA software tool, KÜBLER has now developed this information instrument.

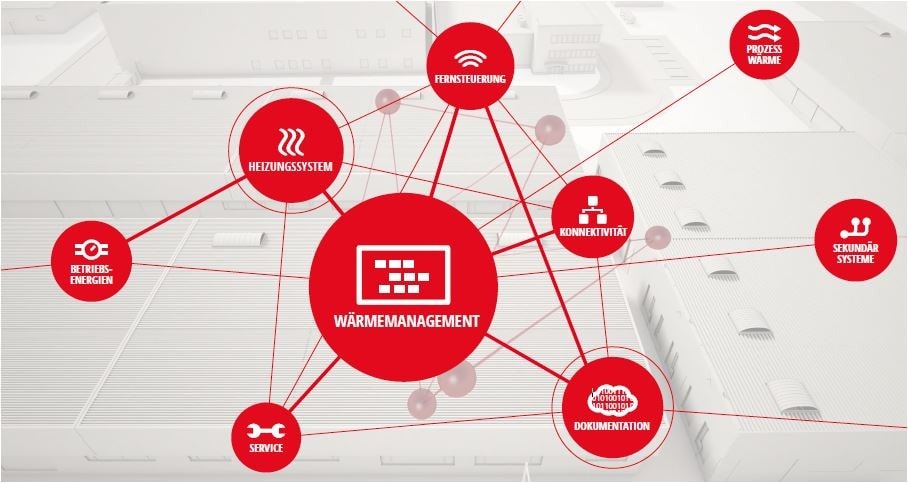

EMMA stands for Energy Monitoring & Management Application. The heat management system is a module of the CELESTRA digital control cockpit and visualizes, analyses, documents and archives all key parameters such as temperature curves, heating output and consumption data. For each individual heater and, if desired, to the exact day or minute. The benefits for users of hall heating systems are considerable. For the first time, the heating process in energy management can be monitored reliably and with high precision. This is a valuable source of information for identifying and localizing deviations from target values and quickly taking countermeasures in the event of energy losses. The fact that the possibilities of the powerful heat management system go far beyond the actual heating process is demonstrated, for example, by its use at a production company in Laubach. By evaluating the data, energy guzzlers such as doors that have been open for too long or leaks in the roof could be detected.

Powerful basis for audits such as DIN EN 50001 and Co.

In practice, however, EMMA is much more than a powerful tool for increasing the efficiency of heating systems. For many companies, certification in accordance with DIN EN ISO 50001, 14001 or a registered environmental management system in accordance with the EMAS regulation plays an important role alongside economic aspects. In Germany, for example, DIN EN 500001 is a prerequisite for particularly energy-intensive companies to be partially exempt from the EEG levy. By recording energy flows and evaluating consumption data, EMMA offers systematic energy management for the industrial heating process as a basis for the above-mentioned audits. A special feature of EMMA is the report function. Summarized in one document, the system provides a complete overview of all relevant data, divided into the various heating zones. A perfect basis for comparing energy flows within the company. And a transparent basis for implementing both technical measures and strategic and organizational management approaches with the aim of continuously and sustainably improving energy use.

Meeting the 2030 climate targets today

Energy efficiency is the central topic that KÜBLER, the hall heating specialist, is committed to. The company has been researching and developing this for 30 years. Successfully, as evidenced not only by the regular awards, including the German Sustainability Award. Today, KÜBLER systems achieve energy savings of 30 to 70 percent compared to conventional solutions. The company is regarded as an innovation driver in the industry and has been setting benchmarks for decades, for example with system solutions such as H.Y.B.R.I.D. or the digital hall heating system WÄRME 4.0. "Our solutions are a good 10 years ahead of today's efficiency requirements - they therefore make an important contribution to a climate-neutral future," says Thomas Kübler. But future requirements are becoming increasingly ambitious. The fact that this path is far from over is demonstrated by the unabated activities of the company's own R&D department. We can therefore look forward to further economically and ecologically relevant innovations from KÜBLER.

-

State Secretary Mario Brandenburg, Member of the Bundestag, in conversation with Thomas Kübler, Dr. Steffen Manser (KÜBLER GmbH) and Prof. Dr. Matthias Rädle (CeMOS) on the subject of research, development and what is needed to reduce CO2 in industry and commerce.

-

The multi-energy IR hall heating system with integrated lighting function has already won its fourth design award in prestigious competitions for innovation and its valuable contribution to the energy transition.

-

Professor Thomas Giel is convinced that the flagship company from Rhineland-Palatinate - KÜBLER GmbH - should be a stop on Climate Protection Minister Katrin Eder's tour of the trade fair. "If you have such an innovative company in Rhineland-Palatinate, then you have to visit it at the trade fair and show that Rhineland-Palatinate is also at the forefront of the heat transition. For this [...]

-

How can the heating challenges of hall buildings be mastered in the energy transition? The answer to this question inspired many trade fair visitors and gave hope for a pragmatic, technologically sensible and at the same time very economical solution to the 65%-EE question. In Hall 12.1 B19, the innovation leader for highly efficient infrared heaters presented three groundbreaking world firsts: FUTURA, FUTURA cool and MAXIMA E-Hybrid.