Reiners + Fürst is one of the leading international companies in textile machine construction. From its headquarters in Mönchengladbach, it supplies the demanding textile industry worldwide with high-quality spinning rings and ring travellers. The innovation-driven company generates an annual turnover of around 15 million euros. Reiners + Fürst is now in its fourth generation of family management

and has stood for high quality standards, reliability and sustainability with its corporate values for over 65 years.

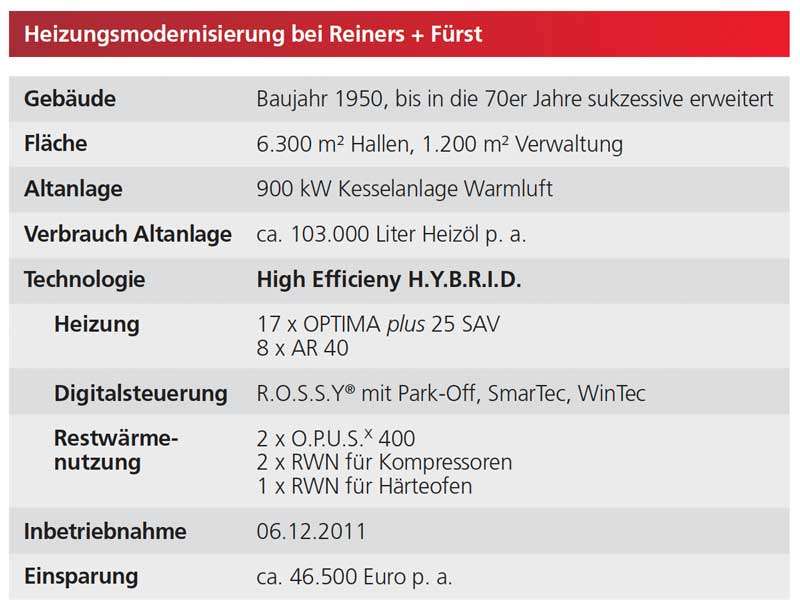

When Reiners + Fürst was planning a new investment in hall heating in spring 2011, one of the first steps was to visit Effertz Tore in Mönchengladbach. The leading fire protection roller shutter door manufacturer in Europe has been operating an energy-saving hall heating system from KÜBLER since 2008. When an independently commissioned energy consultant recommended the KÜBLER system, the decision was made. The old oil heating system was replaced by the H.Y.B.R.I.D. system.

"The combination of infrared heating systems and residual heat utilization brings together the energy flows from heating, curing ovens and compressors."

Initial situation

The L-shaped, elongated building complex on the site of the spinning ring specialist Reiners + Fürst in Mönchengladbach comprises around 6,300 m² of production and storage space with a total of five halls and a 1,200 m² administration building. Since the 1980s, all buildings have been heated by air heaters using two oil-fired systems with an output of 465 kW each. In the winter months, up to 1,000 liters of heating oil were burned there every day. The system was also becoming increasingly unreliable. In spring 2011, Reiners + Fürst realized that a new investment was necessary.

Requirements

"We integrated the question 'What is the perfect hall heating system for us?' into fundamental considerations about saving energy," says Benjamin Reiners, who is the fourth generation to manage the business at Reiners + Fürst. In order to uncover all potential energy savings, the company took advantage of the funding opportunities offered by the nationwide "Energy Efficiency in SMEs" initiative and enlisted the support of an accredited energy consultant from the outset. A catalog of requirements was drawn up together:

- Merging the energy flows

- Maximum utilization of waste heat through integrated heat exchanger

- Optimal use of savings potential

- Significant reduction in energy consumption and costs

- Fulfillment of ecological requirements as a minimum prerequisite

- Reduction of air humidity

- Selective heating of the various workstations as required

- Guaranteed reliable system availability

- Easy to operate and simple maintenance conditions

- 5 to 6 years Amortization period

- Made in Germany

At the same time, Reiners + Fürst used its close contacts with Effertz Tore Mönchengladbach to inspect the H.Y.B.R.I.D. infrared heating system from KÜBLER with integrated residual heat utilization.

Challenges

The conversion work in winter, and even more so during ongoing operations, was a bit of a worry. Benjamin Reiners was also initially concerned about the planning effort involved. After all, the various heat flows were to be combined in one place over long distances and different production areas such as steel rotor production, metalworking, shipping and ring production.

"Ultimately, there were no disruptions at all. The project management was impeccable and the challenges were all mastered together," says Reiners.

Solution

In the search for the most efficient solution, the entire heat flow was balanced at Reiners + Fürst. The aim was to absorb the energy where it is generated, store it temporarily if necessary and transport it to where it is needed. The H.Y.B.R.I.D. infrared heating system from KÜBLER with integrated residual heat utilization proved to be the ideal solution for the renowned textile machine manufacturer:

- The waste heat from hardening ovens and the compressed air system can be optimally utilized by the O.P.U.S.X heat recovery system

- The highly efficient infrared heaters only produce the additional heat that is needed in the building

- The decentralized infrared heat can be used precisely in the hall zones where it is needed

- The small number of roof breakthroughs through the collective gas flue system

- The high flexibility and reliability of efficient infrared technology

- The indirect self-explanatory regulation

- Finally, the exceptional cost-effectiveness of the innovative system

"The use of residual heat completely covers the heating requirements of the 1,200 m2 of office space."

The nationwide initiative "Energy Efficiency in SMEs" is a joint funding program of the Federal Ministry of Economics and Technology and KfW. The program includes consulting support (grants for initial and detailed consulting) as well as investment support (low-interest loans). The funding measures can be used by all companies that meet the EU's SME criteria.

"In the winter months, the old system burned up to 1,000 liters of heating oil per day."

1) In 2004, the resource-optimizing control system R.O.S.S.Y® was awarded the Innovation Prize of the Federal Ministry of Economics for its high functionality, ease of use and measurable contribution to the more economical operation of hall heating systems.

"We assumed a saving of 40 %, we realized 65 %."

Infrared heaters: Powerful energy-saving systems

The high-performance OPTIMA plus line is used to heat the halls, supplemented by standard AR type units. Similar to the heating principle of the sun, the energy-efficient infrared heating systems from KÜBLER ensure pleasant, draught-free working conditions and uniform temperatures in production and warehouses. Between 18 and 22 °C, depending on the employees' requirements.

Residual heat utilization: extra energy for hot water preparation

The use of residual heat combines several systems: the infrared heaters, the curing ovens, which are in operation 24 hours a day with their flame curtains, and the compressed air system with two compressors. The energy generated from the waste heat is stored in two buffer tanks. It completely covers the heating requirements of the 1,200 m² office space. An additional gas boiler is only installed in the basement to cover production-free days, e.g. around Christmas.

Control: intelligence and ease of use

The entire system is controlled by the self-learning control system R.O.S.S.Y® 1). It allows the different heating zones to be individually controlled quickly and easily via a PC. R.O.S.S.Y® independently determines the optimum switch-on and switch-off times and operates the heaters at maximum efficiency depending on shift operation, weekend and vacation periods. R.O.S.S.Y® at Reiners + Fürst is supplemented by additional modules such as ParkOff, which automatically switches off the heaters as soon as they are shaded by cranes. The optimized control of the overall system makes a further contribution to reducing energy consumption at Reiners + Fürst.

Result

"We can only be satisfied," concludes Benjamin Reiners. Heating costs have been sustainably reduced from 71,500 euros in 2010 to around 25,000 euros per year. But the expectations of the innovative and highly efficient heating system have also been fulfilled in other respects after two heating periods. "The working atmosphere is very pleasant," says Heinz Willi Berger, Operations Manager at Reiners + Fürst. The employees, initially skeptical, are also enthusiastic. The indoor climate is no longer so overheated. The bottom line is that both the entrepreneur Benjamin Reiners and the energy consultant are delighted: "The decision was the right one."