CONDENSING BOILER TECHNOLOGY HARNESSES HIGH SAVINGS POTENTIAL IN COMPANIES

"No energy transition without energy efficiency" is the title of dena's "Topics and projects" section on its homepage1 "The best kilowatt hour is the one saved," says Thomas Kübler, Managing Partner of KÜBLER GmbH. Both mean the same thing: It's about curbing energy consumption in general and especially in companies. Because this is an enormous lever for achieving climate targets. And that's not all: energy efficiency also pays off economically if it is approached in the right technological way. Modern infrared heating technology plays an important role here, especially when it is intelligently combined with condensing boiler technology.

Condensing technology converts waste heat into usable energy

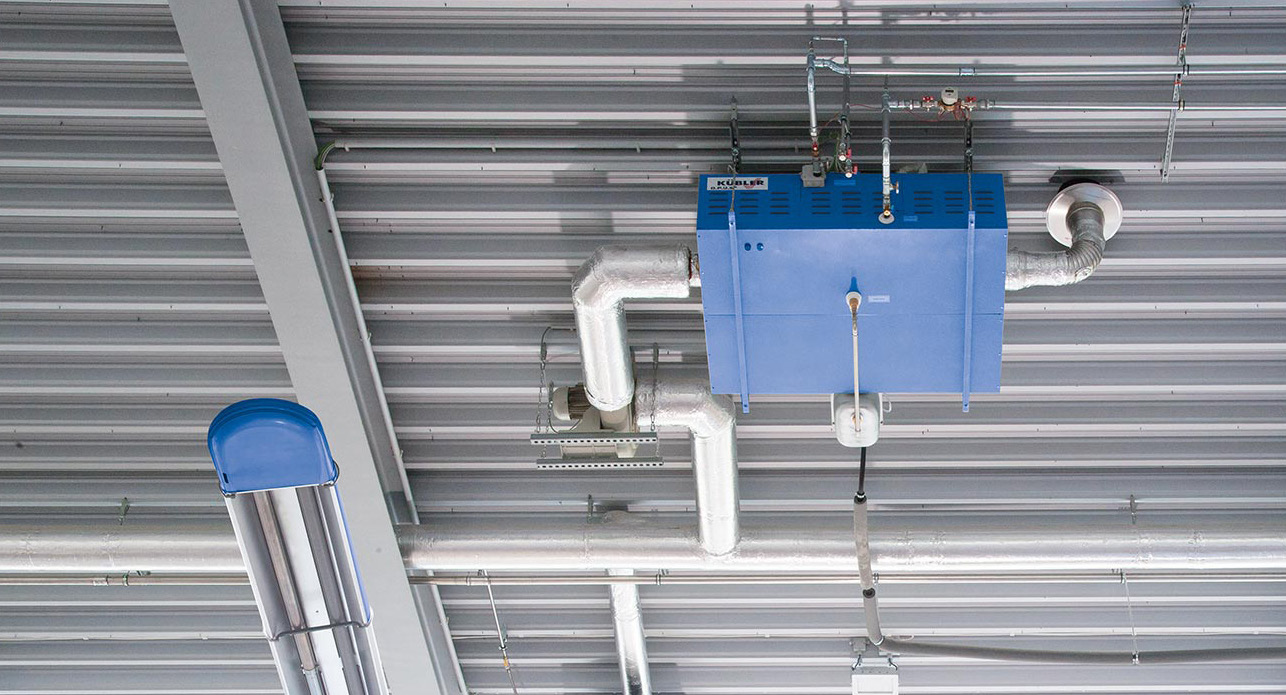

The special feature of condensing technology is that it extracts the condensation heat (known as calorific value) from the waste heat of heating systems, makes this energy content usable and thus significantly increases the overall efficiency of the systems. Depending on the fuel, this is referred to as oil or gas condensing boiler technology. In short, condensing boiler technology is characterized by the fact that it increases the degree of energy utilization and thus energy efficiency.

How waste heat recovery with condensing boiler technology works

The functional principle of condensing boiler technology is basically very simple. Using infrared heating as an example, the energy contained in the exhaust gas is cooled down to the point of condensation and the heat obtained in this way is transferred to a storage medium (usually water). The heated water is fed to a buffer tank and from there, depending on demand, fed into a standard pumped hot water heating network. Water is the ideal storage medium, but other media such as air can also be used and harnessed in hot air blowers, for example.

Start by identifying and reducing your waste heat sources

It is not only heating systems that generate waste heat; depending on the operating mode, waste heat is generated in a wide variety of places. Ovens, machines (especially air compressors), cooling systems and/or uninsulated pipes are probably the classics. Get to the bottom of the causes of unused waste heat by thoroughly analyzing and evaluating energy consumption throughout the company. The next step is to avoid or at least reduce unnecessary waste heat by optimizing processes. The following questions will help you do this:

- Can you avoid idle times?

- Are all systems/processes really running efficiently, or can a few adjustments be made here and there?

- Are some processes perhaps oversized?

- Are there heating or cooling phases that would not be necessary in practice?

- Do you maintain your machines and systems regularly?

- Do you insulate sufficiently?

With a comprehensive analysis, you can already save a lot of waste heat. And the rest? It's best to use it sensibly, depending on your requirements.

Put the energy gained from condensing boiler technology to good use

The practical thing about condensing boiler technology is that you can use the waste heat in a variety of ways to increase energy efficiency in your company. "Hybrid heating" is an important keyword here. This is because waste heat can play a major role in hot water preparation or heating rooms. While this variant of waste heat utilization has already established itself in many private households, it is still far from being used everywhere for heating hall buildings. Yet this building segment in particular has a reputation for consuming a lot of energy due to the dimensions of its rooms. There is great potential for savings here. In the industrial sector, for example, the recovered energy can be used for domestic hot water or for hot water-based (hybrid) heating. This often makes sense for offices or social rooms, which are typically connected to halls. In the sports sector, hot water is often used in sanitary facilities, especially for shower rooms. Where appropriate, hot air can be used via hot air blowers to supplement energy-efficient infrared heating.

Bundle your energy flows for greater energy efficiency

Not only the waste heat from heating systems can be harnessed, but numerous other heat flows in the hall building also offer interesting, efficiency-enhancing potential. Namely when you intelligently combine condensing boiler technology and heating. One example is the H.Y.B.R.I.D. infrared heating system from the Ludwigshafen-based hall heating specialist KÜBLER. The fully integrated solution offers great flexibility in the integration of different technologies and energy sources. For example, the hybrid system can utilize the energy flows from the process (machines, compressors, etc.) at the same time as the waste heat from the heating system. At a textile machine manufacturer from North Rhine-Westphalia, the energy flows from the heating system, curing ovens and compressors were combined in this way. Since then, the heat requirement of 1,200 m² of office space can be completely covered by the use of residual heat.

There are also numerous other possible combinations. What is particularly interesting in view of the usually large roof areas of industrial halls is that the hybrid system, which has won several awards (including "Germany's most sustainable product", German Sustainability Award 2012), can also integrate renewable energies such as solar thermal energy (keyword: Helio.B.R.I.D.). Heat pumps can also be integrated. In addition, the hybrid system is the basis for the implementation of digital hall heating (e.g. WÄRME 4.0), which makes it possible, among other things, to continuously run the system on an ideal line through real-time monitoring of current consumption. The combination of condensing boiler technology and energy-saving heating technology therefore allows you to ensure greater energy efficiency in your company in a variety of ways.

Why you should focus on your company and climate targets at the same time

Only around half of German companies are aware of their waste heat potential - as dena writes in its publication on waste heat utilization as part of the Energy Efficiency Initiative2. This means that an estimated 226 TWh of usable heat goes unused every year. That is 36% of the energy used by the entire manufacturing industry. Clearly, this costs companies an enormous amount of money, but at the same time the unused waste heat has a negative impact on the environment. Around 60 million tons of the greenhouse gas Carbon dioxide evaporate unnecessarily into the atmosphere every year. In view of rising energy costs and climate protection targets, companies simply can no longer afford to do this.

Make environmental protection your economic efficiency measure

The fact that waste heat recovery with condensing boiler technology is achieved with virtually no additional consumption costs should be of great interest to many hall operators. Overall, the integrated KÜBLER residual heat recovery in the hybrid system allows up to 15 percent of heat to be recovered and utilized. Thomas Kübler, founder and managing partner of KÜBLER GmbH Energiesparende Hallenheizungen: "This figure, in addition to our already extremely energy-efficient infrared systems, marks a quantum leap in economical and environmentally friendly hall heating. Energy savings of up to 70 percent* can be realized in the overall system."

* Compared to conventional technologies

How the combination of condensing boiler technology and IR heating pays off in practice

Practical examples show how these values pay off for hall operators. Carbon dioxide emissions were reduced by around 65% by modernizing the heating system with the KÜBLER H.Y.B.R.I.D. system in a production hall of the AZO Group in Osterburken. Specifically, from approx. 226,400 kg p.a. to approx. 79,800 kg per year. Greater energy efficiency was also the focus at Reiners + Fürst. The energy savings achieved by the textile machinery manufacturer during the energy-efficient refurbishment of its production and storage areas were also around 65%. The savings here amount to around 46,5000 euros and 299 tons of Carbon dioxide emissions per year. Incidentally, Reiners + Fürst was awarded first place in the Energy Masters Award in the buildings category in 2014 for the refurbishment of the hall heating system and the integration of residual heat utilization in the hall heating, compressed air and curing oven in the H.Y.B.R.I.D. system.

The bottom line: hybrid heating with condensing boiler technology pays off - especially financially!

Using less energy to generate heat saves money. That is crystal clear. How this translates into concrete figures depends on various factors, such as

- The type and size of your company

- The volume to be heated

- The number of processes that generate waste heat

- The heating system you use

Conclusion: Optimization potential can be found in many different places

Hall modernization, proper insulation, highly efficient heating systems, condensing boiler technology and other options for modern waste heat recovery: there are many ways to increase the energy efficiency of your business and reduce costs. Feel free to contact us and let us discuss how you can use the waste heat from your heating and production processes sensibly instead of disposing of it unused through the chimney.

1 Weblink: https://www.dena.de/themen-projekte/energieeffizienz/

2 Cf. 1445_Broschuere_Abwaermenutzung.pdf (dena.de)

FUTURA IN TRIER: FIRST MULTI-ENERGY INFRARED SYSTEM FOR CLIMATE-NEUTRAL HEATING OF HALLS IN OPERATION

The metalworking company "Die Kanter & und Schlosser" heats its new building variably with electricity, hydrogen or gas thanks to the world innovation from KÜBLER in Ludwigshafen.

"Our motto is progress" is the motto of the future-oriented metalworking specialist in Trier. The company has also applied this claim to the new 2,800 square meter hall, where production has been taking place since 2022. From the building insulation to the PV system, from state-of-the-art fiber laser technology to nitrogen self-generation, the highest energy efficiency standards are being implemented here. One of the most important components: the hall heating. However, the process of getting there has all the hallmarks of an entrepreneurial thriller.

"Initially, we were still thinking about an underfloor heating/heat pump combination to heat the new halls. After all, it is considered energy-efficient and is subsidized by the state," says Christoph Rotsch, Commercial Director at "Die Kanter". However, after consulting with the regional installation partner, it quickly became clear that different technology would have to be used for hall buildings with their huge room dimensions than for living rooms, offices or kindergartens. He therefore contacted KÜBLER, a proven expert in energy-saving infrared heating technology for industrial halls. The decision in favor of the high-efficiency system was made. That was at the end of June.

"We have implemented a whole host of energy efficiency measures in the new hall, from PV to insulation and machine technology. We clearly wanted the same for the heating."

However, the entrepreneur had done the math without the Federal Ministry of Economics. It was all about the future of gas heating systems and whether they made sense. "Kanter & Schlosser" withdrew the contract two weeks after it was awarded. "The uncertainty surrounding the gas supply was simply too great for us," says Christoph Rotsch. KÜBLER then surprised everyone with a world first - developed even before the energy crisis. "In my opinion, we produce the most efficient systems for heating halls. And we have now opened up our high-efficiency technologies to the use of renewable energies," says Thomas Kübler, founder and managing partner of the KÜBLER Group. Obviously at exactly the right time.

"When we got to know FUTURA, underfloor heating was off the table."

"Die Kanter & Schlosser" became a pilot project. "We are always breaking new ground ourselves with many of our projects. We are happy to help shape the process at KÜBLER," says Christoph Rotsch. "When we got to know the FUTURA, underfloor heating was off the table."

The pilot in question is a multi-energy infrared system, also known as multivalent. A world first that builds a bridge to a carbon-free future. It is not for nothing that the new technology is called FUTURA. The energy-efficient infrared heating system can use renewable energies such as electricity or hydrogen. At the same time, biogas, natural gas or liquid gas can also be used, switching variably between the energy sources. This works both in mono mode and in a mix. Depending on which energy is currently available or particularly cost-effective. "In this way, we ensure security of supply and stabilize the grids," says Kübler. "But above all, our solution is economical."

"We are thus ensuring security of supply and stabilizing the grids. But above all, our solution is economical."

The multivalent system went into operation in Trier just in time for the 2022/2023 heating period: the infrared systems work from the hall ceiling in the same way as the sun, which heats everything that is illuminated - people, machines and the hall floor. This means that the heat comes simultaneously from above, below and from all sides. This heat transfer is energy-efficient with savings of 50 to 70 percent. "With the FUTURA, we heat flexibly in terms of time and location," says Kübler, "because we only cover the heat demand that actually exists. After all, the most efficient heating system is the one that isn't running."

"With FUTURA, we heat flexibly in terms of time and location, because we only cover the heat demand that actually exists. After all, the most efficient heating system is the one that isn't running."

The heating is switched on according to demand when and where heat is needed. It is controlled via the CELESTRA control system, which has been expanded to include modules such as WinTec for remote control. The E.M.M.A. heat management system was also installed. It provides "Die Kanter & Schlosser" with full real-time transparency of the entire heating process and makes all data available to the management for audits, such as in accordance with DIN EN ISO 50001.

"The best thing for us is that we can now heat with different energies. In future, we will be able to decide flexibly which is the most favorable for us and when."

"We had full confidence in KÜBLER's more than 30 years of experience right from the start," says Rotsch. Now, around three months after commissioning the new system, "Die Kanter & Schlosser" is very satisfied with the decision. "The best thing for us is that we can now heat with different energies. In future, we will be able to decide flexibly which is the most favorable for us and when." With FUTURA, companies are no longer reliant on gas alone. "We currently only heat with electricity. Now in winter, the PV system covers all our costs from around eleven o'clock onwards." In the old building, the heating had previously blown circulating air into the hall. Every time the door was opened, it got really cold and it felt like it took half an eternity to warm up inside again. "We definitely have a completely different heat quality in the hall now. Much more pleasant, much more localized and no more swirling dust. This has also been very well received by the employees."

"We now definitely have a completely different heat quality in the hall."

Another important advantage Rotsch mentions is the ability to heat the various work areas in the hall building individually or to switch them off when operations there are finished. "We have defined four different heating circuits that we can control with the FUTURA system. It saves us a lot of energy if, for example, the metalworking shop stops earlier on Fridays and the heating can be switched off specifically in this area." Wasting energy would be out of the question for the future-oriented company. This is another reason why they are glad to be away from technologies such as underfloor heating, which cannot be controlled according to demand and has to run at night or even at weekends.

"We have already recommended the new FUTURA technology to others and would do so again and again."

The Managing Director of the innovative hall heating company KÜBLER cannot understand the uncertainty that currently exists in the market. "We have been providing proven solutions for industry for a long time that can reduce energy consumption and CO2 emissions by up to 70 percent and more." However, the current crises have thrown politicians off course to such an extent that urgently needed energy renovations are being put on hold because it is not clear what will or will not be permitted in the future. At the same time, renewable energies are not even available across the board and in sufficient quantities for heating processes in industry and commerce," says Thomas Kübler. "What is certain is that heat pump technology is not a real alternative in halls. If only because companies are deprived of any flexibility to reuse hall areas or change machine set-ups in the future." But the heat pump is also not very attractive economically, regardless of whether it is combined with underfloor heating or radiant ceiling panels. "Companies have to reckon with an investment that is three to four times higher than necessary. And this with much poorer usability, but with comparable energy efficiency."

And the conclusion from "Die Kanter & Schlosser"? Christoph Rotsch: "We have already recommended the new FUTURA technology to others and would do so again and again."

The new CO2 tax: What does it mean for your company?

Since 01 January 2021,CO2 pricing, also known as the "CO2 price" or "CO2tax", has been in force. In the eyes of many entrepreneurs and consumers, this is an additional burden, as the new levy will cause energy prices to skyrocket, thereby increasing heating costs, among other things. Learn more about the newCO2 tax and its consequences in this article.

NowCO2 also has a price in Germany

To protect our livelihoods, the global community agreed at the 2015 UN Climate Change Conference in the Paris Agreement to limit global warming to well below 2°C, and preferably to 1.5°C. To achieve this, we must be greenhouse gas neutral from 2050. Since then, more and more measures have been developed to achieve this goal - both internationally and at the European and national levels. The European Union aims to reduce greenhouse gas emissions by at least 55 percent by 2030 (the year of comparison is 1990). With the so-called EU ETS (European Union Emissions Trading System), there is emissions trading for almost the entire energy industry. The goal: to reduce climate-damaging gases by issuing a limited number of emission rights as an incentive to do so and trading them freely on the market. Outside of European emissions trading, however, such an incentive has been lacking. In the National Climate Protection Program 2030, the German government therefore adopted price incentives in addition to subsidy programs and regulatory measures.

The transport and heating sectors are particularly important, as they account for around one-third of climate-damaging emissions. CO2 emissions in the heating segment alone are to be reduced by 80% by 2050. The way to this was paved when the Fuel Emissions Trading Act (SESTA) came into force at the end of 2019. Based on this, greenhouse gas emissions now also have a price in Germany. Since 2021, Germany has relied on its own additional instrument for reducingCO2 emissions, known as theCO2 tax, in the form of national emissions trading (nEHS). The federal government is thus setting clear goals:

- Achieving the minimum targets of the EU climate protection regulation

- Meet national climate protection targets, especially greenhouse gas neutrality by 2050.

- Improve energy efficiency

How does theCO2 tax work?

The newCO2 tax, which has been in force since January 01, 2021, relates to the transport and building heat sectors. It stipulates that the combustion of fossil fuels such as heating oil, liquefied petroleum gas, natural gas, coal, gasoline and diesel will be "taxed" with immediate effect by a fixed, gradually increasing price. This is intended to create incentives to use less energy and switch to more environmentally friendly alternatives.

But how does theCO2 tax work now? Companies that place these fuels on the market must acquire so-called "emission rights" with certificates. These allowances are based on a predetermined threshold quantity of emissions; their number is reduced from year to year. Who acquires these certificates differs depending on the fuel. In the case of natural gas, for example, these are the municipal utilities as those who supply the end consumers. Certificates for petroleum products have to be purchased mainly by producers (e.g. refineries) and traders. The cost of these emission allowances will be passed on to end users, i.e. residential customers and businesses, with the result that prices for heating fuels and motor fuels will rise from 2021 onwards.

What additional costs will you incur with theCO2 tax?

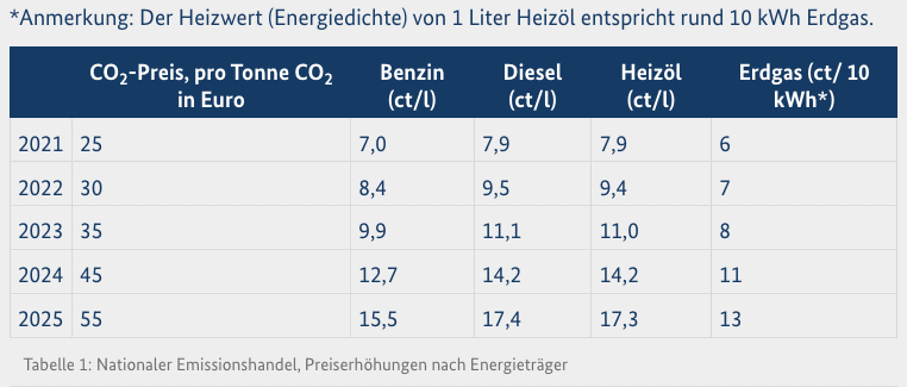

To enable business and consumers to gradually adjust to the new system, fixed prices will initially apply to theCO2 tax. They will start at 25 euros per metric ton ofCO2 in 2021 and rise gradually until 2025. From 2026, the scheme envisages that the cost of theCO2 tax will initially develop in a price corridor between €55 (minimum) and €65 (maximum) per metric ton ofCO2, depending on the market, and will move to a free trading phase from 2027. In 2025, a decision will be made at the political level on further pricing. Thus, fossil fuel costs will increase gradually, most moderately for natural gas at 6 cents per 10 kWh in the first year.

What does theCO2 tax mean in concrete terms and what should you do?

First and foremost, theCO2 tax means two things:

- Heating and mobility are becoming more expensive.

- Energy sources, energy use and technologies must be reassessed and made much more efficient to absorb rising costs.

In line with the motto "The cleanest and cheapest energy is that which is not consumed in the first place," the German Federal Ministry for Economic Affairs and Energy is focusing on resource conservation with its Deutschland macht's effizient campaign, among other things. The principle of "efficiency before substitution" applies here. For example, if you are already currently using modern, decentralized efficiency technologies for heating that use fossil fuels but are very energy efficient, there is less need for action. By the way, from a height of more than four meters, you are exempt from the Renewable Energy Obligation of the GEG when heating with decentralized technologies in the new construction of hall buildings.

Energy efficiency is not only a necessity from an ecological point of view, but is also increasingly important from an economic point of view. Therefore, of course, in the long term you should not hesitate to modernize your heating system or switch to alternative energy sources. This can also be natural gas in the future - because: The upcoming feed-in of hydrogen (power-to-gas) and the possibility of producing natural gas synthetically will make this energy source increasingly greener and more renewable. For more information, read our article on future technologies for heating modernization!

What opportunities does business have to save costs despite theCO2 tax?

The good thing about the SESTA and the newCO2 tax is that policymakers are using them to create real incentives to make companies and consumers more energy efficient, to use climate-friendly energy sources and to develop innovative products. Moreover, with the price regulation set until 2026, there is planning certainty and a sufficiently large window of opportunity to react. So as a company or consumer, you decide for yourself: Does it make more sense for you to pay theCO2 tax or to counteract the cost increase with suitable measures? Our tip: try to achieve your goals with as little energy as possible and examine the use of regenerative energies in the long term. This way, both sides benefit: the climate and your company. Below we give you examples of how you can increase energy efficiency:

- Increased thermal insulation

- The use of energy-efficient technologies

- The use of heat recovery and residual heat

- The use of intelligent control technology

- Switching to energy sources with lower emission values (e.g., natural gas instead of fuel oil).

- The integration of solar thermal and other renewable energies

How can rising costs be avoided?

- § Section 11 of the SESTA ensures financial compensation to companies by way of a hardship clause if they are unreasonably affected by rising prices. Prerequisites are:

- Fuel costs account for more than 20% of the total cost of operation.

- Additional costs incurred by the company as a result of the introduction of the SESTA would exceed 20% of gross value added.

In addition, double burdens resulting from the use of fuels in a plant subject to EU emissions trading are to be avoided as far as possible.

It is also planned to provide relief to those companies that would experience disadvantages on the international market as a result of theCO2 tax. For many foreign competitors,CO2 pricing and the resulting increase in fuel costs are no longer an issue. The solution comes in the form of the so-called "Carbon Leakage Regulation": Those who suffer disadvantages on the international market as a result of theCO2 tax will receive financial compensation. This is how Germany wants to prevent companies from relocating. However, affected companies must demonstrate that they have an energy management system in place and are already working to reduce theirCO2 emissions. They must then use the benefits to further reduce theirCO2 emissions.

Will my climate protection measures be funded?

At the national level, the federal government supports investment in climate protection through a number of comprehensive, and in some cases updated, funding programs and grants. These include, for example, the Federal Support for Efficient Buildings (BEG) or the Federal Support for Energy Efficiency in Business. You can apply for these programs either as a grant through BAFA or as a loan subsidy through KfW. In addition, costs incurred for energy consulting are also subsidized.

What options can companies use if the investment costs are too high?

Anyone who cannot or does not want to invest, but still wants to use modern efficiency technologies to heat production halls and warehouses and thus reduce the additional costs caused by theCO2 tax, is well advised to use HeizWerk. This rental model is doubly interesting from an economic point of view - firstly, because companies incur neither investment nor depreciation expenses. Second, because the energy cost savings from efficiency technologies in energy retrofits of existing facilities are usually significantly higher than the rental amount. With the positive result that the companies even have extra money in their coffers after the modernization.

Conclusion: Start reducing your company'sCO2 emissions!

Even if theCO2 tax makes prices rise only slowly, you should not wait too long. Get an overview of your savings potential and reduceCO2 emissions and energy consumption in a targeted manner. Particularly in hall buildings, heating modernization promises great savings potential. Feel free to do the math with our freeCO2 calculator and get an initial estimate of where and how you can still reduce!